Evolve or sink

New technologies to help woodshops stay competitive in today’s fast-paced market

As with sharks, businesses need to keep moving forward or they’ll sink to the bottom. For woodshops, that normally begins by upgrading machines, tools and workflow to improve both the quantity and the quality of work.

The following is a round-up of some of the newer technologies that may help a shop owner stay current, and competitive.

CNC routing

Automation isn’t really an option anymore. With a tight labor market and the need for speed, it’s the only way forward.

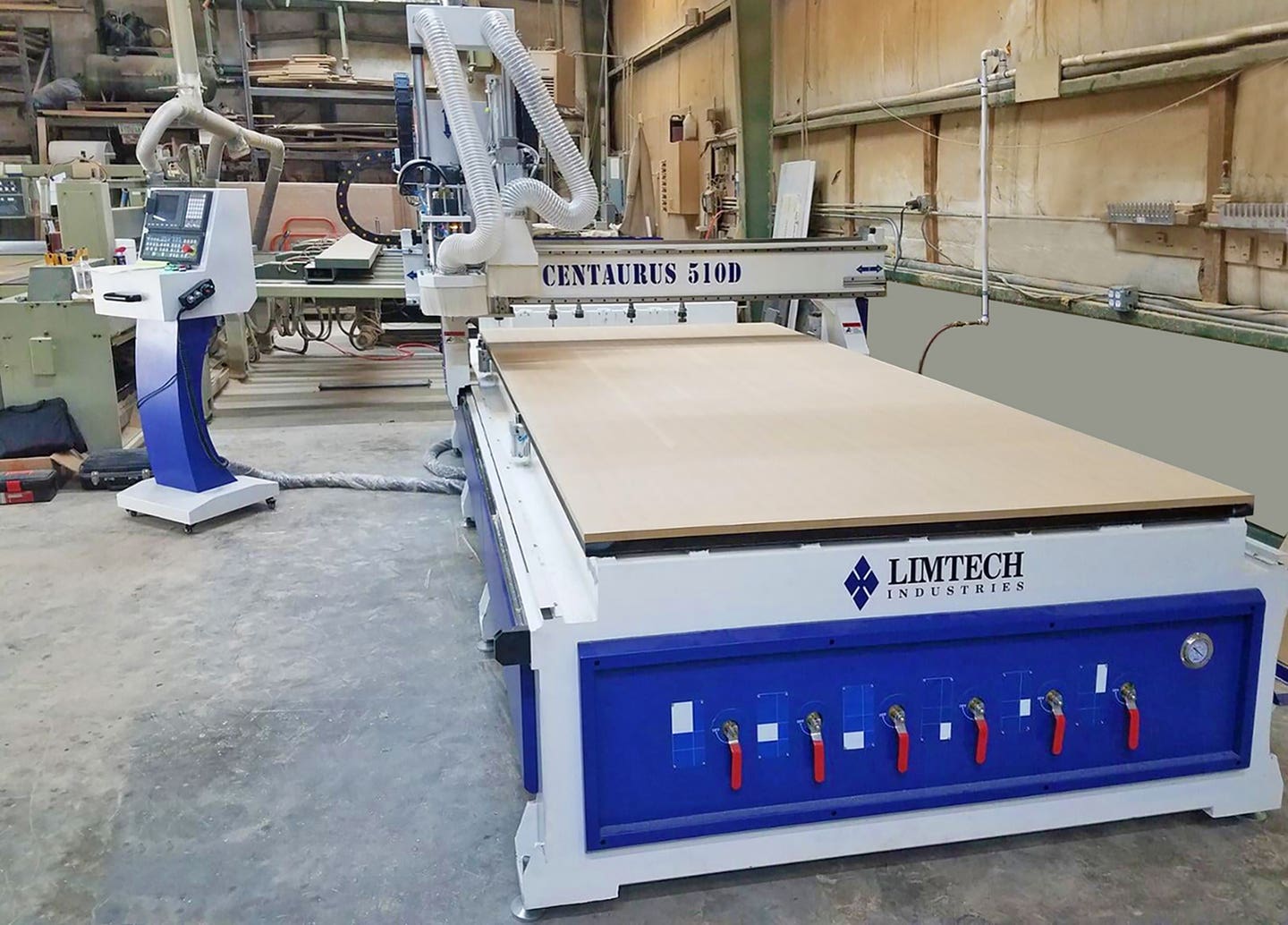

Shops looking for their first CNC might consider the Centaurus Series from Limtech Industries (limtechindustries.com), which has many of the design and operating features found on the company’s larger machines, but with linear tool-changing instead of onboard carousel tool changers. Centaurus is designed for nested manufacturing and it has an inline 32mm line-boring system in the X and Y axes.

Shops that own an Anderson America (andersonamerica.com) CNC can instantly upgrade with the company’s new QR Code Support System for customer service. A woodworker with a technical issue can point a phone at one of the QR keys and gain instant access to comprehensive guides and video tutorials.

Laguna Tools (lagunatools.com) has added its new KX24, a desktop router with several notable features including a 15" touchscreen, an ‘ultra-quiet’ spindle, and a 24" x 48" work-zone..

A new generation of the LC Series of CNC from Techno CNC Systems (technocnc.com) features a new ball screw technology. Available in three sizes (4 x 4, 4x8 and 5x10) with a 12" gantry clearance, this machine comes standard with a 12-hp automatic tool changer, eight-position tool rack, and pneumatically operated vacuum hood. There’s also a four-zone vacuum T-slot table and a handheld controller.

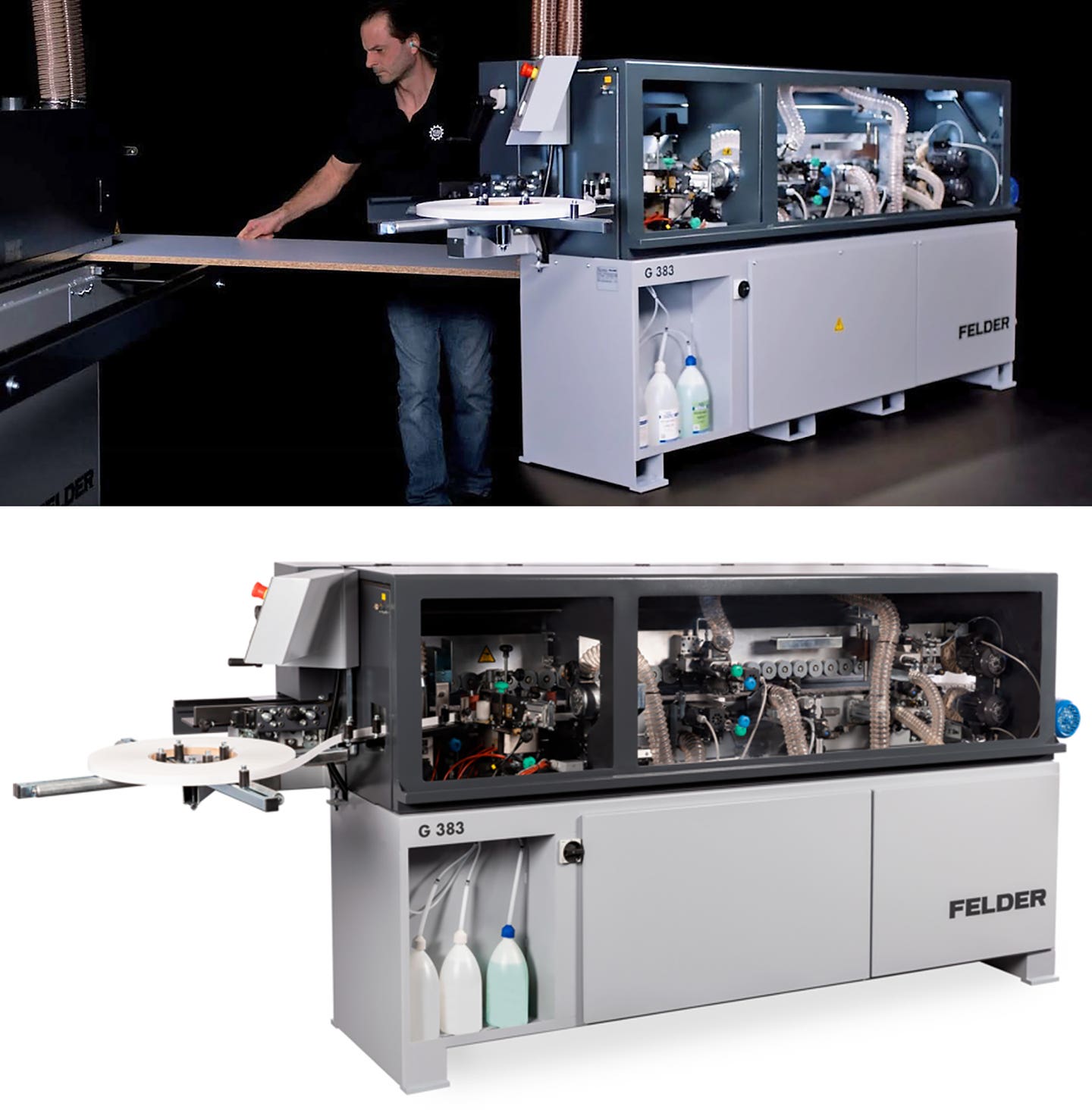

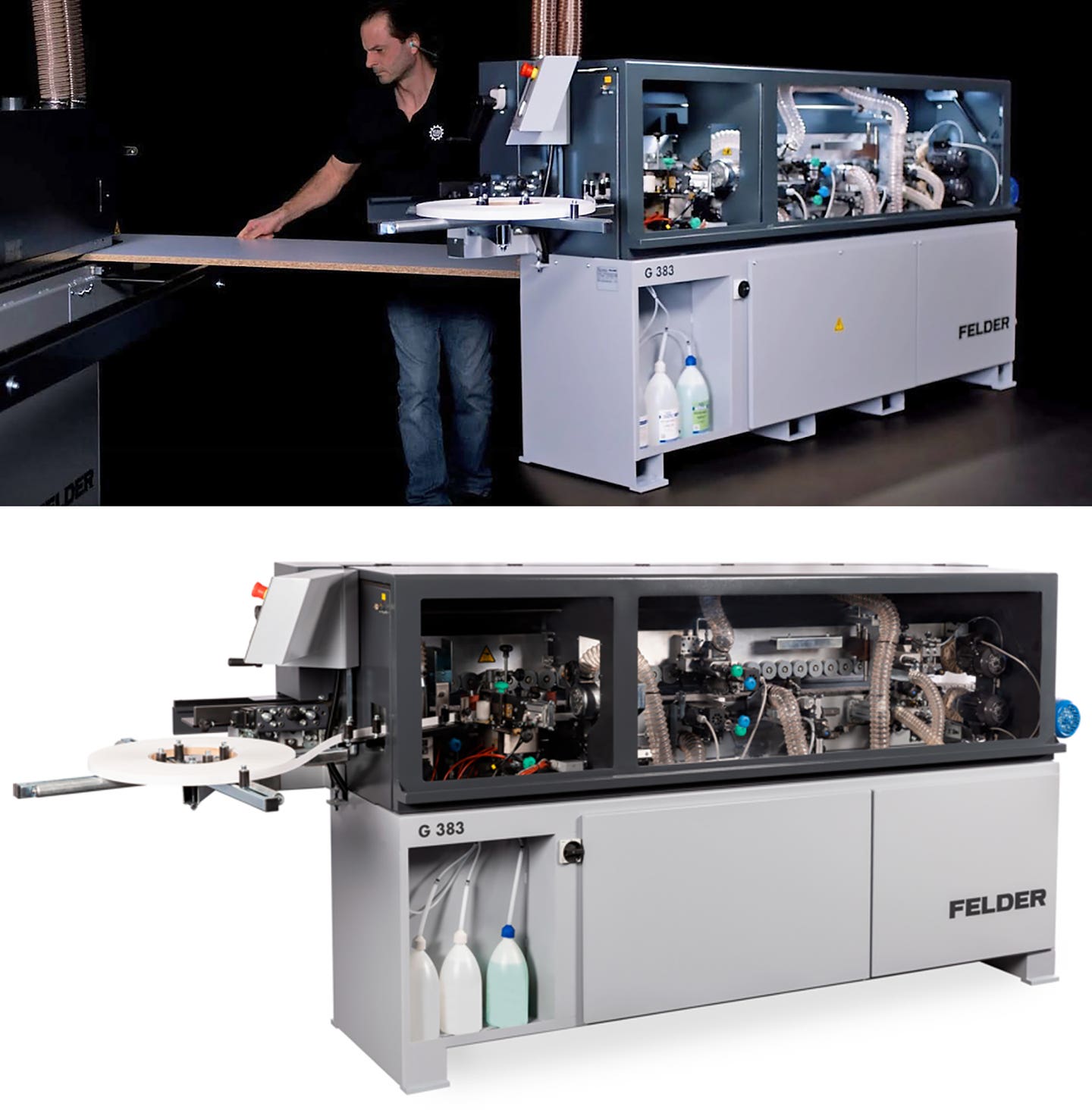

Edge banders

Among a family of new banders from Felder Group USA (felder-group.com) is the compact G383, which has chain conveyors, a 7" touchscreen, and a pre-milling unit. It handles banding from 0.4 to 5 mm thick, and panels up to 50mm (about 2”) thick. The G383 can be configured with features including a Teflon-coated interchangeable glue pot, and spraying units for cleaning and release agents. It also comes with a corner-rounding unit and spaces for up to three additional finishing units.

Handling and finishing

SNX Technologies (snxtechnologies.com) says that its new nVision C1.5 is its most budget-friendly machine yet. This is a contour banding machine that’s designed for open-ended and tight inside radii parts. Equipped with0 a new controller, the machine is capable of edge banding and trimming an inside radius as small as 7/16″. It has 20,000 rpm ER20 collet-type spindles top and bottom, and an articulating vacuum support arm. The C1.5 can band and trim open-ended parts up to 8 feet in length and can apply edge banding from 0.5mm to 3mm thick. Additionally, it can handle parts up to 60mm high and uses standard EVA hotmelt glue.

From moving parts around the shop to raising materials for infeed or clamping them securely on a worktop, Martin Woodworking Machinery (martin-usa.com) offers a family of vacuum and lift carts from Barth that can organize and speed up the production process in any workshop. One of the most interesting is the VakuuCar+, a manual workstation that is well worth a look for shops thinking about workbench solutions.

Upgrading to a Guffey system can help eliminate bottlenecks at the finishing booth. The company (guffeysystems.com) makes the PivotPoint and PivotLine. The PivotPoint lets doors be rotated to spray, and is designed for small batches or small booths. The PivotLine takes that concept to another level. Rather than just holding a door or drawer in one place and feeding the operator via mobile racks, it automates the whole journey. Parts are delivered on mobile racks, suspended from rails to slide into and through the spray booth, and then moved out after coating, again without anyone touching any surfaces.

Saw Trax Mfg. (sawtrax.com) sees safety as an area where woodshops can upgrade, and the company makes a lineup of products that serve that concept. Its catalog includes vertical panel saws that let a woodworker stand upright; ergonomic dollies for moving materials and finished goods around the shop and jobsite; and ‘reach’ tools that help keep feet on the floor and shoulders out of harm’s way.

Joinery and profiling

The new Rebel Pocket-Hole Joiner from Kreg Tool (kregtool.com) is powered by a brushless 20-volt Ionic Drive motor and is designed for portable use. There’s no need to pack a drill or clamps, and it sets up tool-free.

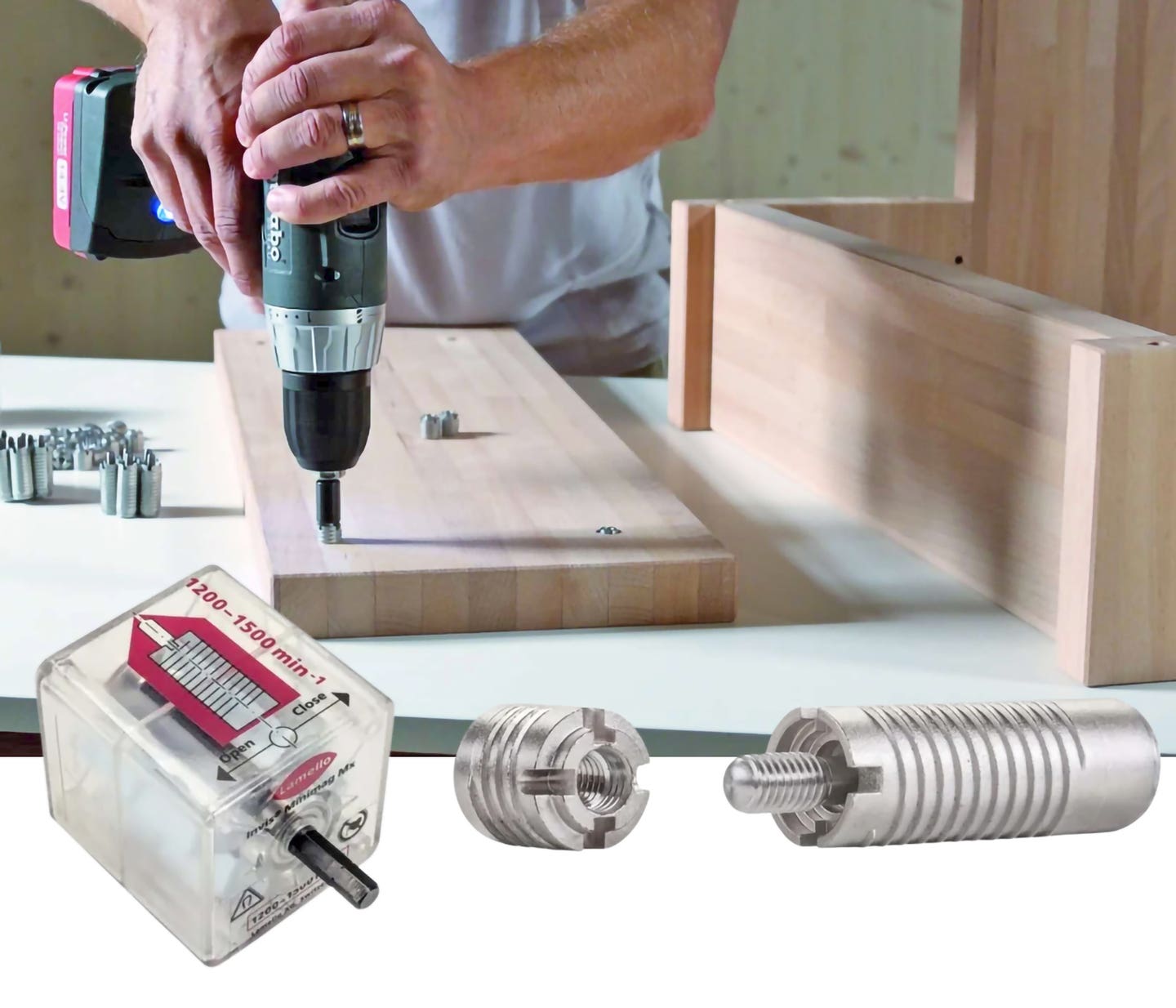

Upgrading joinery methods can be a real timesaver and one of the newer options here is the INVIS connector from Lamello (csaw.com). This invisible, reversable system saves time and effort by allowing a shop to join parts with a completely hidden fastener that can be unscrewed as needed, so it’s ideal for RTA, flat-packed casework. The INVIS magnetic actuator (the plastic box) is simple to use. Just chuck it in a drill, place it on the workpiece parallel to the connector, and pull the drill trigger to tighten. A rotating magnetic field drives the joint together, and a tapping sound indicates that it’s snug. To detach, simply reverse.

Wouldn’t it be nice to be able to make all the parts for a raised panel door on a single machine, without changing cutters? That’s exactly what the new CS-55PAAU from Lobo Castaly does (lobomachine.com). It’s an automated raised panel door shaper, with a 6" tall stackable spindle that has enough power to cut an arch or oval without having to precut the part to rough size. Table movements are hydraulically powered left and right, and movements in and out are pneumatic. Heavy-duty air pistons hold work tightly during the cutting process.

Shops building dovetail drawers in-house may wish to visit Macoser (macoser.com) and have a look at more than a dozen Omec brand Italian engineered dovetailing machines.

Attaching face frames to boxes has always been tricky and time-consuming. The Blind Stapler (blindstapler.com) is a pneumatic staple gun that does this job without pocket screws, nails, or putty. It will never leave a mark, so cabinets can be pre-finished before assembly. The patented design lines up the frame and then allows a narrow staple to be shot in diagonally from the back with no visible marks that require filling and sanding.

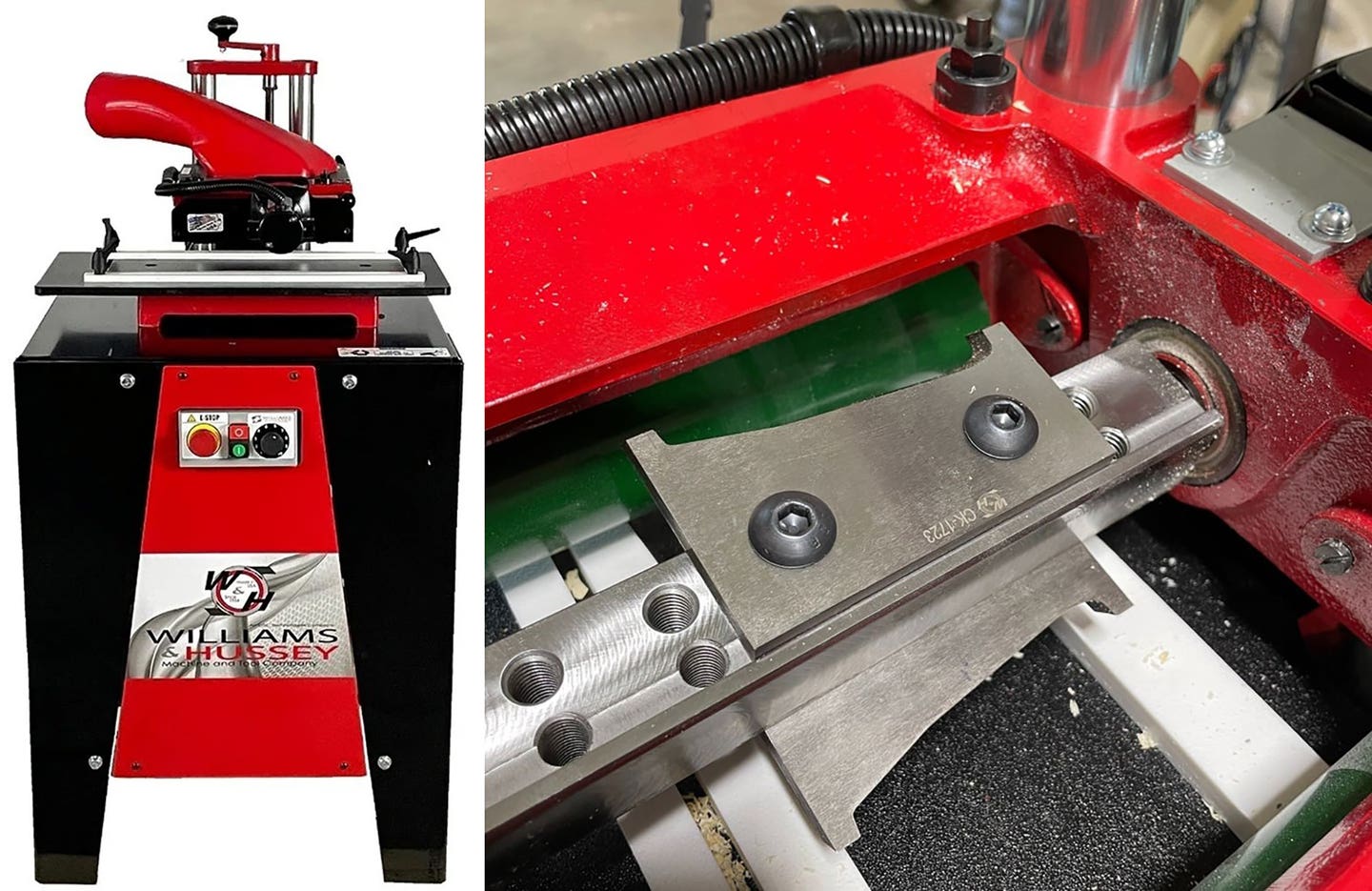

Woodshops using a lot of trim or linear moldings might wish to consider upgrading to an in-house molder. Williams & Hussey (williamsnhussey.com) has been building those since 1954. Machines are available in either single or 3-phase power, with a variable speed rate up to 19 fpm. And woodworkers who already own a W&H molder can visit the Upgrades page on the website to add variable feed control, improve dust collection, increased cutting precision, or ways to modernize an older machine.

For smaller shops looking at harvesting their own lumber, Wood-Mizer (woodmizer.com) has introduced the LX30 Portable Sawmill. It handles logs up to 22" in diameter, with a maximum cut width of 21-1/2" and a 7-1/2" depth of cut. It has a 9-½-hp engine and uses 1/8" thin-kerf sawmill blades.

Dust control and sanding

One of the most profound upgrades for any woodshop is more efficient dust collection, and to that end Cantek (cantekamerica.com) has introduced a new 10-hp machine called the CBS10. This is a cyclone collector with a HEPA filter, a remote control, and a quick release for removing the coarse dust bin. The HEPA filter also has a quick release system to remove and dispose of fine dust particles.

Sanding the faces of edge-glued panels can be upgraded with the new G0404 from Grizzly Industrial (grizzly.com). This 11" benchtop oscillating drum sander oscillates 29 times a minute from side-to-side , which minimizes sandpaper clogging and heat buildup. One can turn off the oscillation for figured woods or unique projects. The machine has a 1-hp motor, a 5" diameter hook-and-loop sanding drum, and a variable speed conveyor belt.

Oliver Machinery (olivermachinery.net) has introduced a new 6" x 48" benchtop edge sander, the 6301, that offers big machine features for smaller shops and budgets. The main table is 17.3" x 10", and the machine runs on standard household current.

The new DEROS RS 600X from Mirka (mirka.com) is a 750-watt portable disc sander with a low noise level, adjustable speed from 700 to 2500 rpm, and optional slow-start. It’s lightweight at less than 4 lbs. and has a low 4.5" profile. There’s an app that monitors vibration, and available accessories include pad savers and a shroud that directs dust.

Machine Tool Camp (machinetoolcamp.com) makes a cabinet door robotic sander that includes fully automated loading and unloading, a Door Sense program that recognizes and measures raised panel, arched, Shaker, MDF and other door types, and automatically changes the sanding media. Cutting, trimming and assembling units are also available.

Sanding out router and knife chatter marks on trim or molding can be time-consuming, so the Chatternator (profilesander.com) was designed by Colorado woodworker Bill Grom to solve that. It’s a patented profile sander that can be located at the outfeed side of a molder. Its sandpaper drum removes chatter on parts being fed by a powered conveyor. The drum has sandpaper flaps/fingers in various sizes that can reach hollows in a molding profile.

Gibbs Group North America (gibbsgroupna.com) has introduced a robust Cup Brush Sander that has a delicate touch. Replacement brushes and abrasive are low-cost, and the machine has a touchscreen controller. There’s an automatic cleaning function that leaves parts dust-free and ready for finishing, and differently sized machines to fit any size shop.

Catching fine wood dust at its source is more efficient and safer than letting it become airborne, and Sandman Products (sandmanproducts.com) makes both downdraft sanding tables and dedicated sanding booths that do just that. Among them is the Sand Pro SBP108 portable sanding booth that has side panels that are hinged and fold in when not in use. The company’s eight Sand Pro tables range from 60" x 33" to a full 96" x 48" and the most popular model, the DL7236, doubles as a workbench.

Clamping

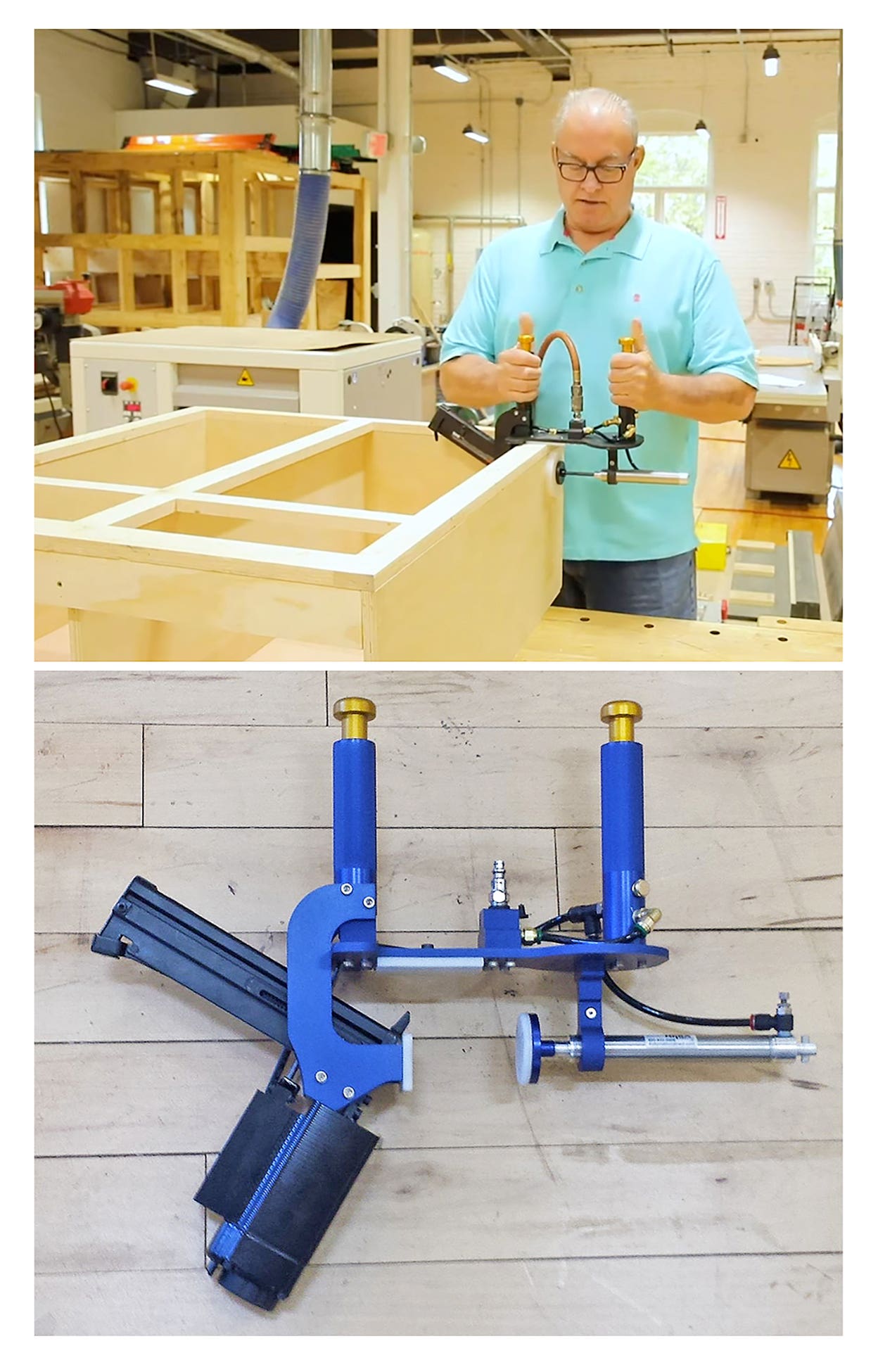

The Squeeze Tight is an automatic hydraulic clamping station from Pro Edge Technology (proedgetechnology.com) that squares up and clamps casework. A woodworker simply places the glued-up cabinet on the conveyor and the machine does the rest. There’s no programming, constant machine tending, or manual adjustments.

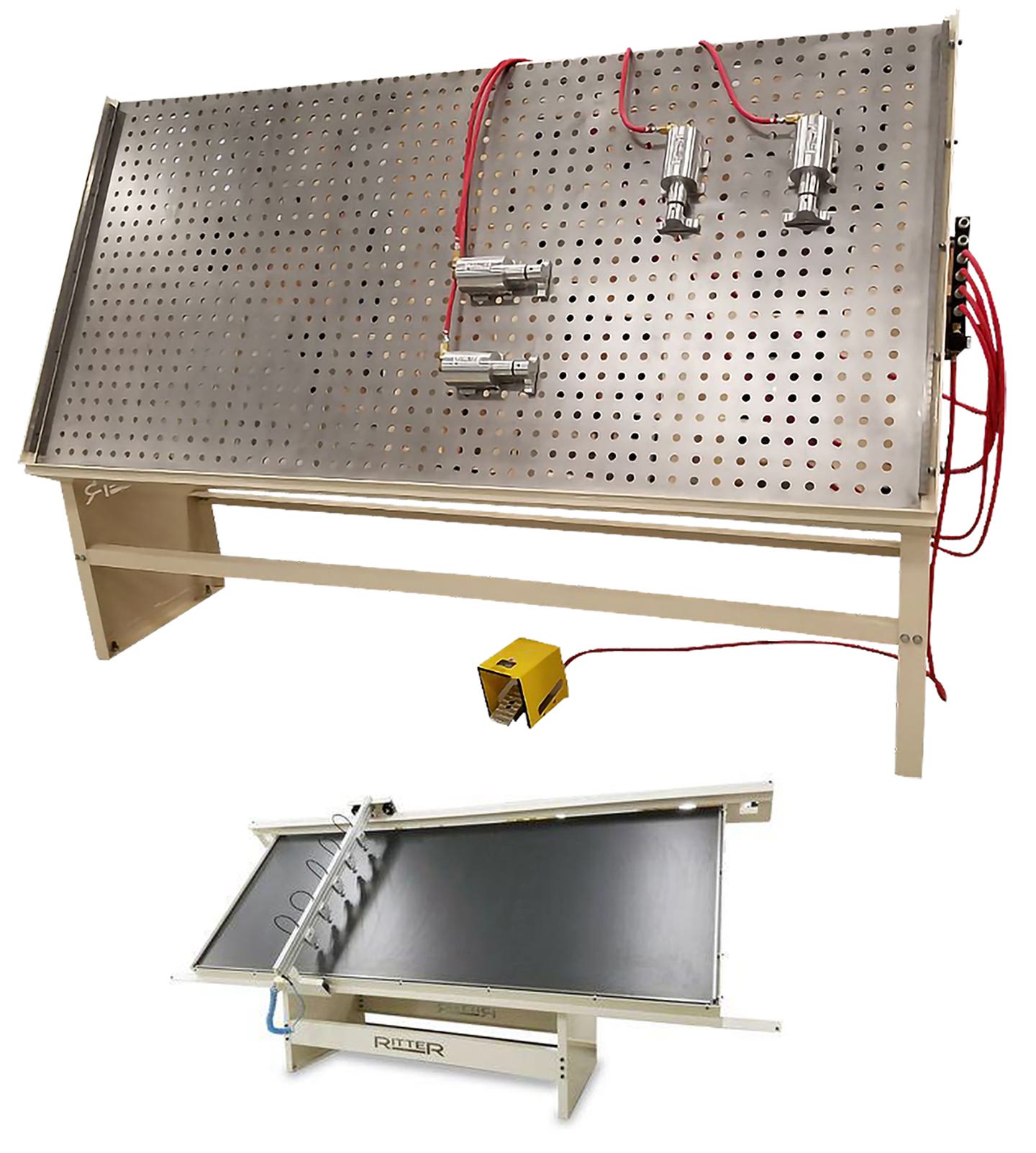

In addition to pocket hole, line boring and sanding machines, Michigan-based Ritter Machinery (rittermachinery.com) also makes face frame and door clamping tables that sit at an angle, so gravity helps when inserting parts. Cylinders on beams hold the parts for flush and tight joints on pocket-screwed face frames. And Ritter’s door clamping tables have adjustable pneumatic clamps, squaring bars, heavy-duty steel frames, perforated steel tables, and built-in dust collection. They can also be upgraded with extra clamp cylinders, manifold assemblies, and foot treadle assemblies.

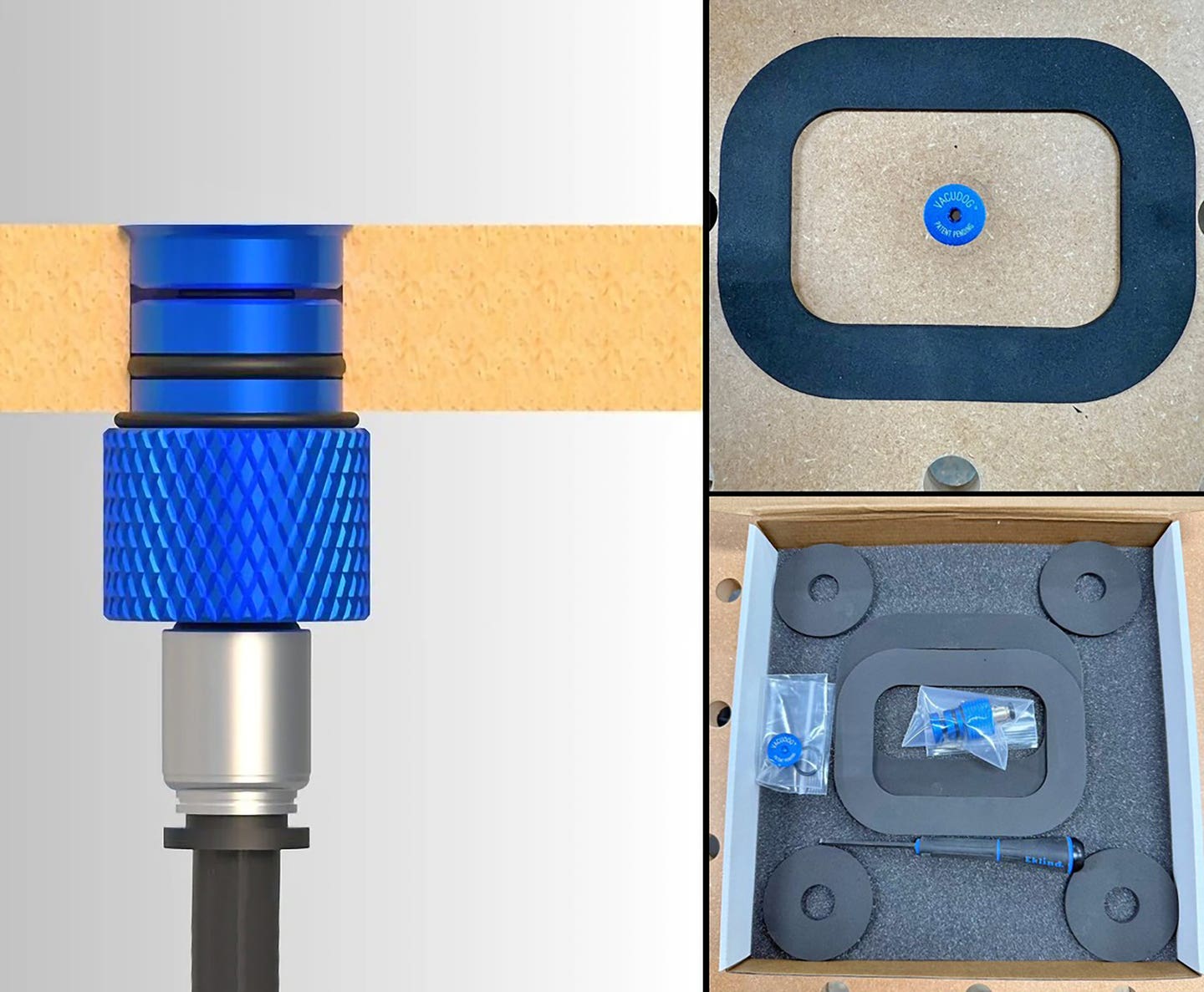

TrackTubes (tracktubes.com) are an aluminum extrusion with a T-slot in each face, and woodworkers use them for miter saw and drill press fences. The manufacturer introduces the VacuDog, an aluminum plug that locks into a 20mm bench dog hole. When connected to a small vacuum pump, it becomes a clamp.

Cutting

The basic technology of band saws hasn’t advanced much in decades, but Harvey Industries (harveywoodworking.com) says it has changed that by launching the 3-hp Alpha A-15, which the company calls “the world’s first intelligent bandsaw.” The 15” saw features sensors to monitor blade tension, drift, speed, and table angle.

Adding an upcut saw can be a big timesaver for shops that require multiple parts in solid wood. The RazorOptimal from RazorGage (razorgage.com) is a programmable optimizing saw system that combines an automatic saw measuring system with a Cyclone 600 upcut saw. It has automated crayon-defecting technology where the system scans material for defects such as splits, knots and other wood defects.

A vertical panel saw adds three important upgrades to a woodshop. It saves floor space, simplifies material handling for large sheet goods, and augments the safety of employees. Safety Speed Mfg. (safetyspeed.com) makes about a dozen models to suit just about any shop’s physical size and product output. These machines save backs from injury, eliminate table saw kickback, reduce the operator’s chances of contacting the blade, and make both rip and cross cuts. Some smaller models are portable for jobsite use, and others can be ordered with SawGear or TigerStop systems. The top-of-the-line automated unit, the SpeedWorx, provides X, Y, Z, and C axis cuts.

SawGear (tigerstop.com) is a simple and intuitive automated stop that easily attaches to an existing miter saw, drill, or punch. It eliminates tape measures and manual fences, and increases accuracy. TigerStop is a stop and positioning system for a wide variety of machines and it can push, pull and position material up to 180 lbs. It turns an existing manual machine into a fully automatic, lean manufacturing asset, and can be upgraded to optimize boards for defects.

Maksiwa (maksiwa.com) makes a full line of traditional woodworking machines, including a sliding panel saw that can be a significant upgrade from a standard table saw. The BMD.3200.IR has a 10-hp motor, advanced CNC-controlled rip fence, a scoring blade, an industrial grade frame, an intuitive touchscreen interface, and a built-in dust collection system.

Rockler (rockler.com) has added the Wixey heavy-duty rip fence and rail upgrade for table saws (item 76178). It has a 72" long heavy-duty aluminum rail with an analog scale that measures 36" right and 12" left of the blade. The steel fence glides on rollers and has two aluminum faces with T-slots for attaching feather-boards and other accessories.

Last year, SawStop (sawstop.com) introduced its Revolution Miter Gauge, where setting angles is quick and easy using the intuitive geared dial system. It has increments of 1, 1/2, 1/4, or 1/10 degrees with a positive ‘click’ in each notch. Or a woodworker can bypass the gear system for free turning.

Sometimes the required workshop upgrade isn’t the machine or its accessories, but simply the blade. Total Saw Solutions (totalsawsolutions.com) makes and sharpens circular saw blades but also specializes in ultra-thin blades. At approximately 1/16" thick, the Micro-Kerf was designed for tasks such as glue-line ripping and cross-cutting applications on miter saws.

Software and power tools

Smart machines, performance apps and other digital advances can be huge upgrades in the workshop. Many of these are brand-specific, such as the App Suite from Weinig (weinig.com) which is available for Android, iOS and as a web application. It lets a shop monitor and manage machines in real time. Weinig also offers Control Suite as a single-operator solution for controlling production lines.

A handheld router can be immediately improved with the addition of the Micro Fence (microfence.com). This system turns a hand-held router into a precision milling machine for straight, circular and elliptical applications, and it can be fitted to more than sixty models of routers, compact routers, laminate trimmers, and high-speed rotary tools.

No matter what machine or tool one thinks about, MasterGage Tools (mastergage.com) has probably found a way to enhance its precision and accuracy. The company slogan is ‘Master Your Machines”, and relying on their expertise in alignment, measurement and calibration for woodworking machines can be a great start to upgrading any workshop.

When a woodshop owner is thinking about improving the production line, that process can be easier when using a single supplier. SCM Group NA (scmgroup.com) builds more than 17,000 machines each year in its three Italian factories, bringing the best of European engineering to the woodshops of North America (and the rest of the planet, too). The catalog includes CNC routers, full CNC machining centers, edge banders, panel saws, bore and dowel machines, wide belt sanders and more.

Whether it’s moving up to CNC, automating processes, or perhaps adding an aftermarket improvement for accuracy, any of the innovations mentioned here can help a workshop upgrade.