Beyond three axes

How aggregates transform standard CNC routers into multi-directional machining centers capable of edge drilling, bevel cutting and complex joinery

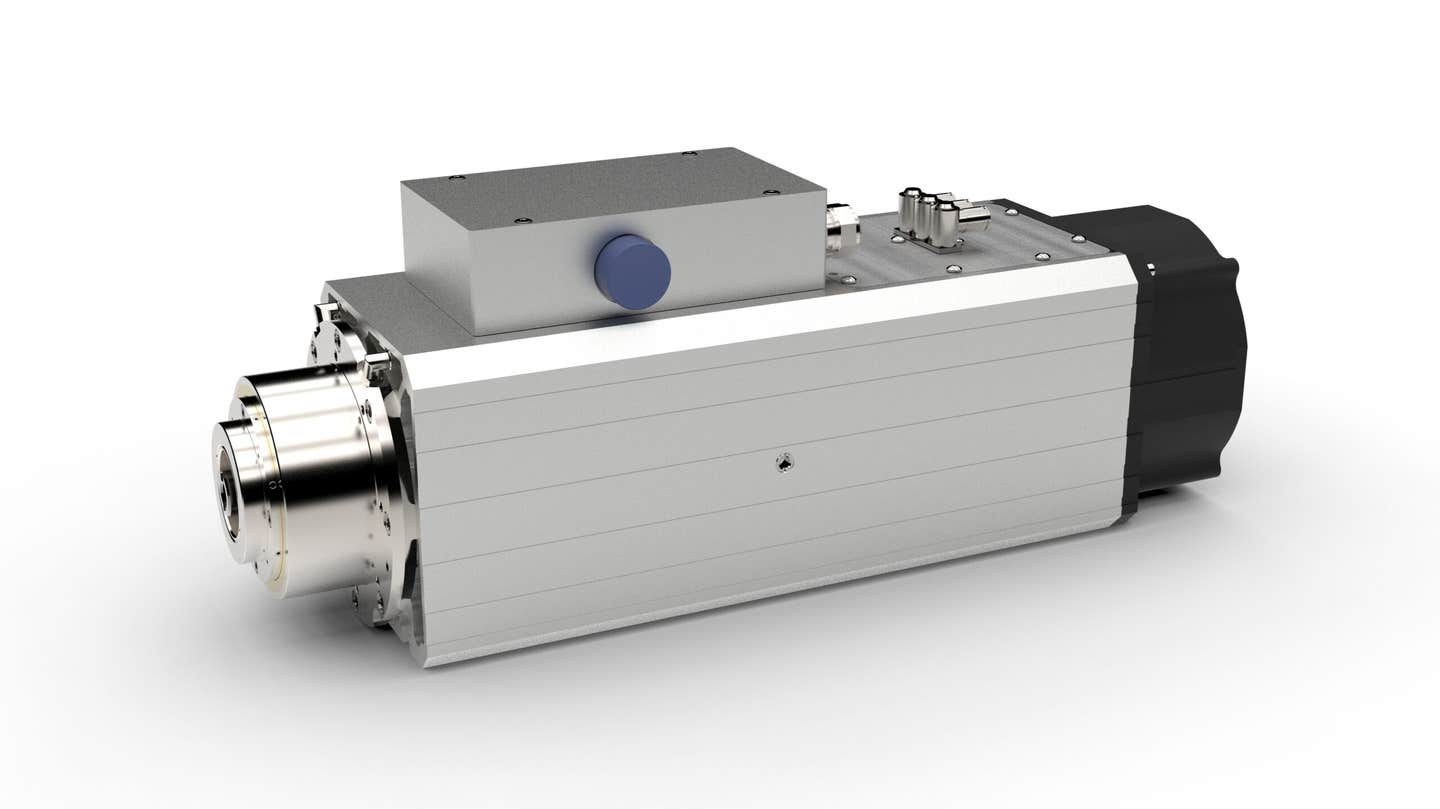

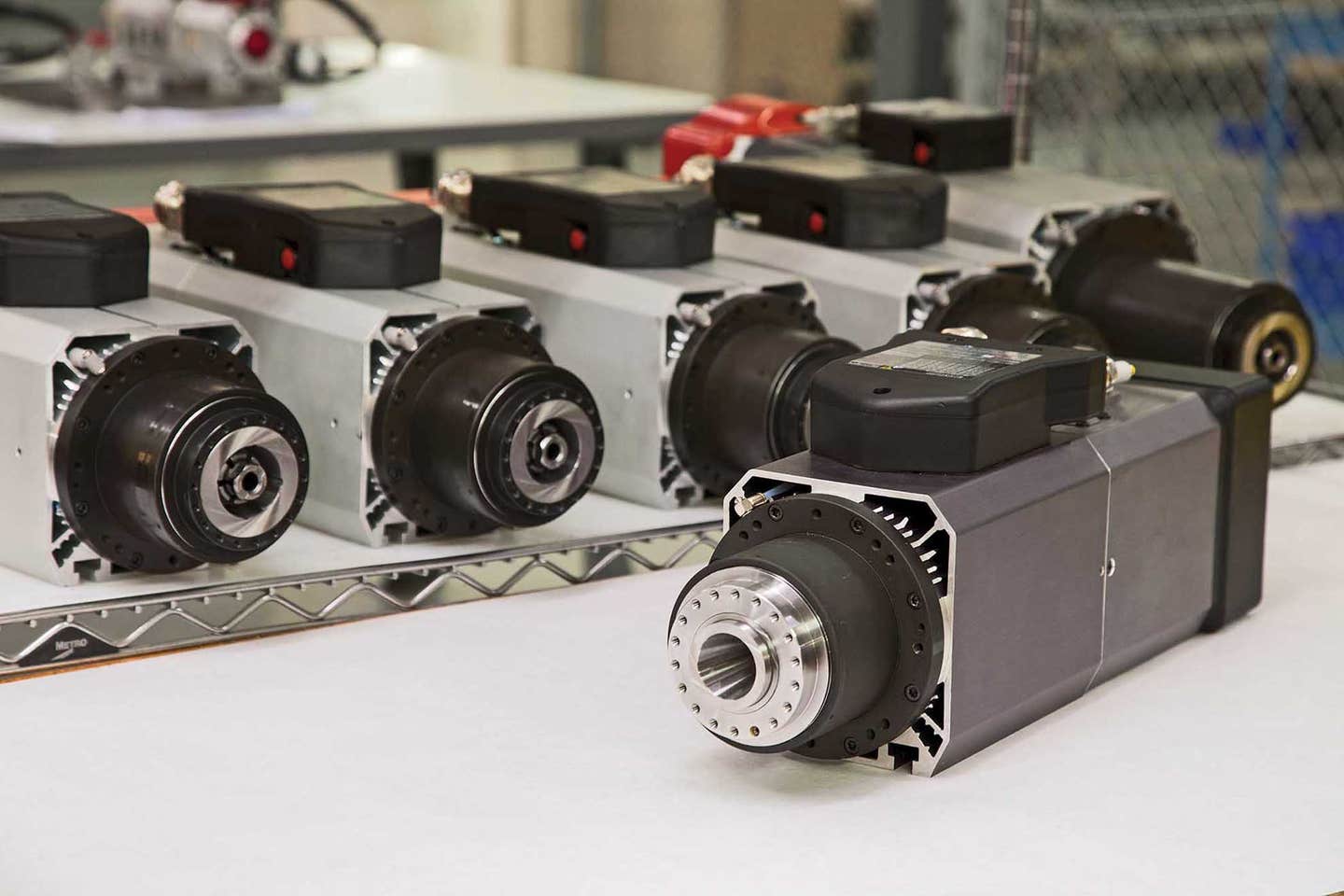

From small to large, every CNC uses some sort of motor to spin the tool. This may be a hand-held router motor, but on industrial CNCs and machining centers, it will be a spindle. At any size or horsepower, a spindle differs from a hand-held router motor in two important ways; First, it is a constant duty motor, designed to run for hours at a stretch. Router motors are rated for intermittent use. Second, spindle motors are controlled by an inverter which maintains a constant rpm in the motor even when the load changes. This consistent rpm makes for better milling results.

When purchasing a CNC, you will likely have a couple of options for spindle selection; the manufacturer has already chosen the best matches for the machine at hand. Be open to your vendors about your needs and they should help you find the best fit. Horsepower can be important but should not be the only criteria you use to decide. The tool holder type matters based on your needs and the type of tool changer that will best serve you will depend on the workflow through your shop.

Like any equipment, maintaining spindles is critical. Most industrial spindles use air to actuate tool changes and to pressurize the spindle body to prevent dust from getting inside the motor. This steady airflow through the motor when running can be problematic if your air supply is not dry. The pull studs that hold the tools and the bearings that support the shaft should be monitored and inspected according to the manuals.

If needed, spindles can be replaced or rebuilt. If you need a new spindle, your machine manufacturer can help you get one, or you can order from the spindle manufacturer as well. Precision Drive Systems (PDS) is one company that can rebuild a used spindle for about half the price of a new replacement, and often in less time than shipping in a new one. PDS recently announced that they will begin offering a new line of spindles in the second quarter of 2026.

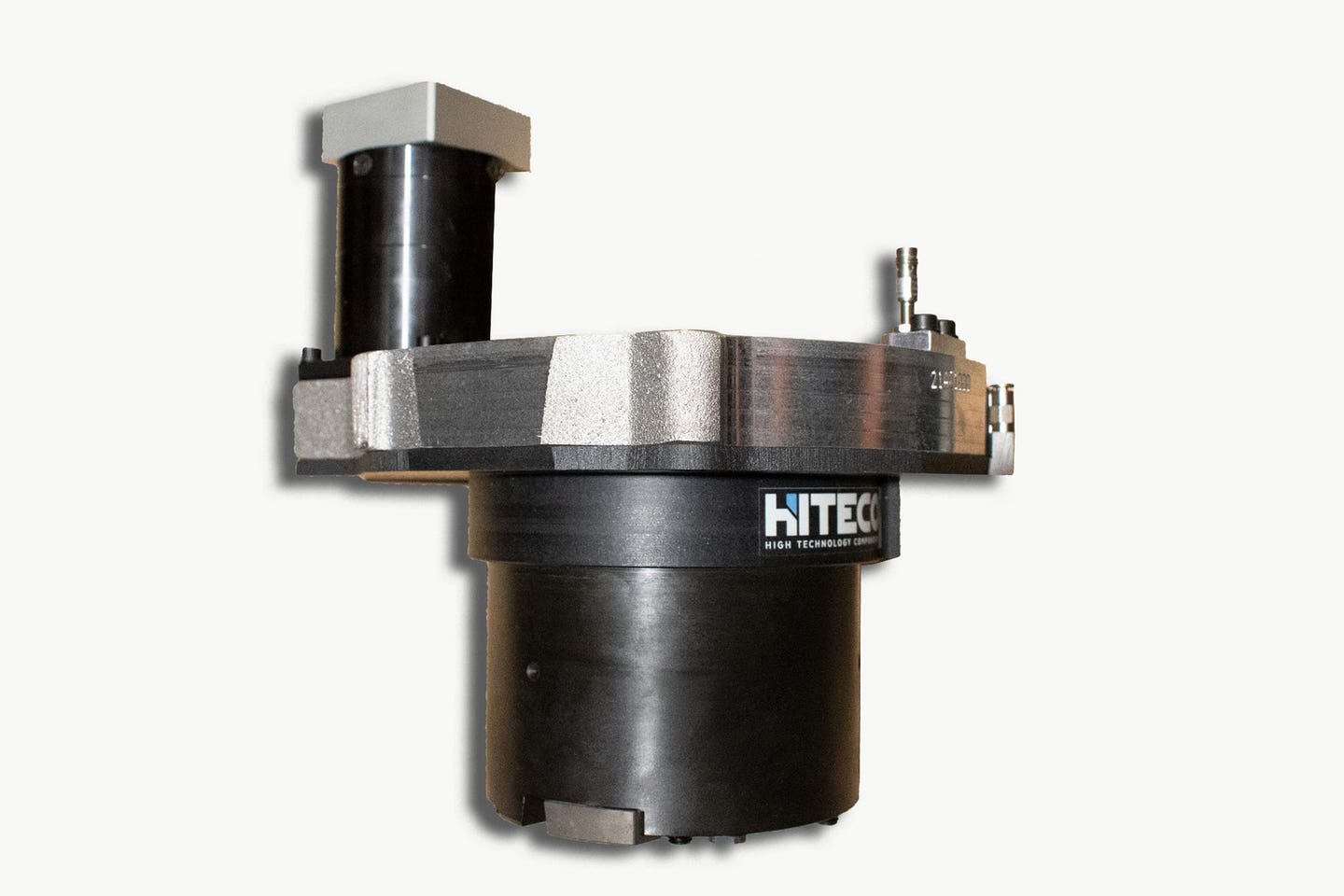

Three-axis CNC machines generally have the spindle mounted perpendicular to the machine bed allowing for a broad range of cutting and shaping operations. But what if you need something more like boring edges, sawing or bevel cuts? You can look to aggregates to add capability to your machine. Aggregates are basically a gear box that changes the rotation axis of the spindle to another angle. Typically, 90 degrees, but it can be a wide range of angles. Aggregates can be quite simple or massively complex, but almost all of them change the spindle rotation to another direction.

Types of aggregates

aggregate head.

Let’s start by looking at simple aggregates that change the vertical cut into a horizontal one.

Drilling holes or milling slots in the edge of a panel is the most basic aggregate function. The rotation is translated to 90 degrees from the spindle with gears. This horizontal gearbox may have a pair of opposed collets, one collet and one saw arbor, or four collets, and each collet can hold a drill as well. Simple aggregates like this are manually loaded into the spindle, which is fitted with an adapter collar that orients the aggregate to the X or Y axis and fixes it in place. Programming is a bit more complex, but usually only requires filling in the parameters of the hole or slot needed; the software manages the actual movements.

With a single bit mounted, the aggregate can drill or mill into a part edge in one direction. With opposed shafts, opposite edges can be milled, and with a four-way head, any edge of a panel can be worked. Fitting one of the drives with a saw blade allows for slot cutting and trimming parts in either X or Y. These operations require clearance around the workpieces to accommodate the aggregate body. They are not typically used on the flat bed of a panel processing CNC.

An exception to this is a copy aggregate, which has a floating ring that precisely controls the depth of cut on the surface of a panel. This is highly useful as it automatically maintains the cut depth of engraving even in panels that may have slight thickness variations. There are also aggregates that act as a square chisel mortiser. At last year’s Ligna show, Benz Tooling exhibited its new Soffiarro aggregate. It does not change the axis of rotation; the bit cuts perpendicularly, but it features four adjustable blower nozzles for cleaning out kerfs to improve cut quality, dust extraction and reduce the cleanup necessary when changing sheets.

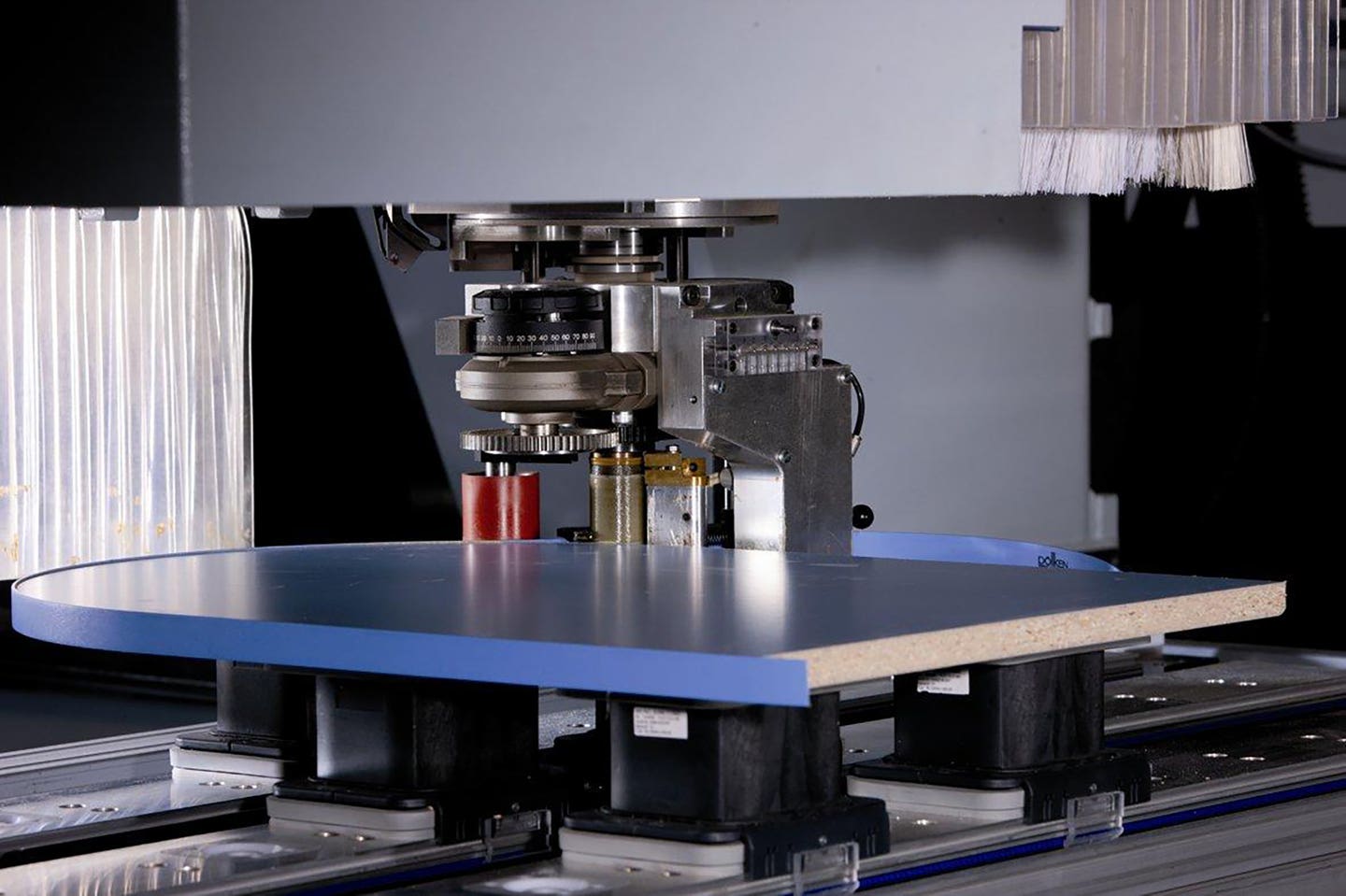

Other aggregates use gearing to allow for a bit or blade to work at an angle other than 0 or 90 degrees. These tilt heads can drill holes, mill slots or even saw bevels at whatever angle needed between vertical and horizontal. The angle of the bit is set manually by the operator before loading the machine. Many of these tilt heads are also capable of being set to a rotation angle. This means that the operator can set them to mill along X or Y, but also along an edge that is angled off the axes. This sort of capability adds a lot of options for companies making furniture parts or even doors and windows. There are even aggregates that can literally reach underneath a part to mill the underside, or “D Face”, of a panel. Adding a lock set mortise under a door in this fashion will save an entire second milling setup, adding significantly to the bottom line.

These simple aggregates are set in position manually. They have no provision for rotating them automatically between the X and Y axis. For that, you need a C-axis motor attached to the spindle. A C-drive collar is fitted with a drive motor allowing the gearbox to be rotated automatically by the machine. With a C-axis drive, the single horizontal bit mentioned above can be rotated during the program run to drill or mill at any angle through 360 degrees. Saw blades can score or trim panels along any side or at any angle. Router and drill bits can work all four edges of a workpiece without needing four output shafts or the operator to change the aggregate position. It is easy to see the advantage of the C-drive even when accounting for the added cost and programming complexity.

Other aggregates may be as simple as drill banks that cut shelf and dowel holes or as complex as a saw that can automatically rotate to cut bevels along any line. Benz Tooling even offers a chain mortiser aggregate for very deep pockets. This is especially useful for hidden hardware installations. Obviously, the heavier and more complex the aggregate is, the more attention must be paid to the CNC machine that will use it. Many machines may be able to be fitted with simple aggregates after purchase, but for more complex operations like Homag’s contour edge banding aggregate, you may need to specify a machine built to handle the accessory.

Maintenance & software

All this gearing being used to change the rotational direction requires attention and maintenance. Digital infrared thermometers can be used to monitor aggregates in real time, allowing operators plenty of warning if temperatures climb during use. And the manufacturer’s maintenance schedule always needs to be followed.

Aggregates are much heavier than a typical bit in a tool holder. They can usually be loaded and unloaded from the spindle by hand, but they can be used with the right tool changer. You will want to check your tool changer specifications to find out if it can support the weight of an aggregate or even has the room to mount one.

The software used to program an aggregate can be much more complex than needed for typical CNC operations. And aggregates are not easy to blend into more automated cabinet CAD/CAM packages, so be sure to ask both the aggregate vendor and your CAD/CAM provider about the programming issues. Most companies will use aggregates infrequently, so it may be advantageous to have two CAD/CAM packages in house: One for the aggregate and a second for day-to-day use. It can be programming everyday jobs using the more specialized software an aggregate requires. If you find you are looking at an aggregate for just one task, it would be a good idea to make sure that there isn’t a simple tool option or secondary operation that can meet the need without the complexities of adding an aggregate to your operations.

Aggregates can add a literal new dimension to your CNC capabilities. There is a surprising variety of options available, and if you have the need, they can be very valuable. As always in business, education is key. Combining the right machine with the proper aggregate on the correct job can pay big dividends and open a new range of operations for your company.

Sources

Benz Tool (benztooling.com); GDP Tooling (gdptooling.com); Hiteco (hiteco.net); HSD Mechatronics (hsdmechatronics.com); Homag (homag.com), and Precision Drive Systems (spindlerepair.com).

Originally published in the January 2026 issue of Woodshop News.