Dust collection dos and don’ts

From airflow dynamics to filter selection, a guide to keeping wood dust under control

Repeat after me: Effective dust collection is never “an option.” It’s an integral part of what you do to keep shop air breathable. Woodworkers have used dust collection for years, but even long-time professionals sometimes misunderstand, neglect or, more likely, simply under-plan their systems. Wood dust is more than annoying. Fine airborne dust can ruin finishes, pose a fire hazard, and cause permanent lung damage. It doesn’t matter how big your shop or how many employees you may have, you should understand how shop air moves and how dust behaves. Then, tackle both.

There are lots of dos and don’ts. Let’s take a look at the essential basics, and some accessories that can make a difference.

Do: Plan the system — Don’t: Build In reverse

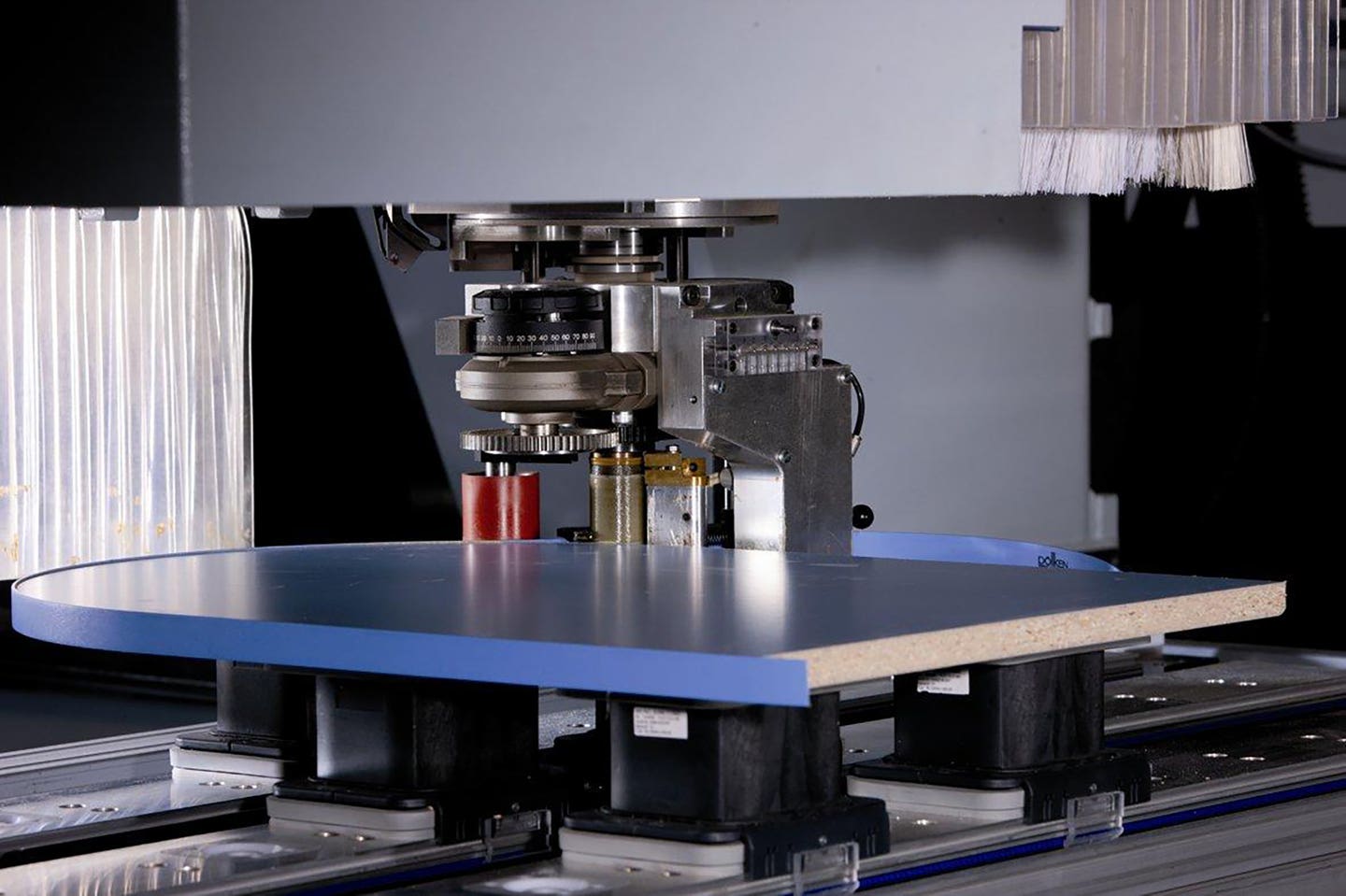

Dust problems begin at the planning stage — or rather, the lack of one. A collector squeezed in after machines are in place is always a compromise. If you have the luxury of designing your shop from the ground-up, begin with a layout, noting where each tool goes and which (if any) will run simultaneously. Ideally, your collector should be positioned smack in the middle of your layout, or near tools with the most/largest chips — table saw, planer, jointer, and router — to keep duct runs short.

Longer ducts, bends, and flex hose create resistance, so the fewer you have, the stronger your airflow. Use smooth metal ducting where possible and keep transitions gradual to reduce drag. My small shop does fine with 4" ducts, but the main ducting in larger shops should start at 5" or 6", branching off 4" drops to individual machines.

Keep in mind that you’re not just designing a simple chip vacuum, but a total airflow system for smooth flow from pickup point to collector with minimal turbulence. Plan ahead for new machines by adding a capped branch. It’s cheaper and easier to do now, rather than rebuilding or extending ductwork later.

Do: Size collectors properly — Don't: Expect a shop vacuum to do It all

They both suck dust, but dust collectors and shop vacuums operate on completely different principles. Vacuums move smaller amounts of air at high pressure, fine for sanders and other portable tools. Dust collectors pull large volumes at lower pressure, just what you need for the big chips produced by planers, jointers and other stationary machines.

A 2- to 3-hp collector, pulling air at 1,200 to 1,800 cfm, is a good starting place for regularly used stationary tools. Bigger isn’t always better: It wastes energy, creates more noise and can even collapse a thin flex hose. Instead, shoot for balance with enough power to effectively pull in the dust without being so powerful that there’s a loss of static pressure caused by turbulence or friction.

Study manufacturer specs and airflow charts when shopping for collectors. The difference between 1-½ hp and 3hp, or 4" and 6" ducting, will affect whether your system captures dust or just blows it around the shop.

Do: Control the fine dust — Don't: Judge cleanliness by sight alone

Big, heavy chips are great — you can see them fall right out of the air — but the fine stuff floating around that you can’t see is the real danger. Particles less than 10 microns can stay airborne for hours; longer if there’s a lot of air movement. That’s plenty of time to get into your lungs where it can trigger long-term respiratory issues.

The air may ‘look’ clean but seeing dust and measuring it isn’t the same thing. Actually, test your shop’s air quality for some hard numbers instead. Handheld air-quality meters adequate for small-shop use run about $150-$300. They can be enlightening, identifying which tools generate the worst fine dust (I’m looking at you, sanders), and verifying that your collection strategy is working.

For optimal performance, use high-efficiency filtration bags. An even better option is to ditch the bags and instead use pleated filter canisters. Canisters rated at MERV 15 or higher catch 85 percent of dust particles from 0.3-1.0 microns, and 90 percent from 1.0-3.0 microns. A two-stage cyclone collector can improve the efficiency of any filter type by separating heavy chips into a dedicated container while directing only fine particles to the filter. The cleaner you can keep your filters, the more powerful your suction will be.

Do: Keep the air moving smoothly — Don't: Create blockages or static

Airflow is the ally of dust collection; resistance is its enemy. Every extra foot in length, and every elbow, constriction or sagging hose reduces the stream. Ductwork should be straight as possible. Use high-radius elbows or replace sharp 90-degree turns with separate 45-degree connectors to soften bends. Short lengths of flex hose is fine for machine connections but use rigid ducting everywhere else.

Blast gates are great at directing suction where needed, as long as you remember to use them. Place gates close to machines and within easy reach of tool power switches. Wired gates that automatically open when turning on a tool, or a remote control clipped to your belt, will save time and help maintain consistent use.

Static electricity is another hazard related to airflow. Dust particles can build a static charge surging through ductwork, particularly PVC and other plastics. The risk of static igniting dust and causing an explosion is low, but unexpected shocks due to static are irritating at best, and sometimes painful. Metal ducting should be directly grounded with copper wire, while a bare copper wire running along the inside and outside of a PVC duct can minimize electrical surprises. At the very least, grounding lessens static that turns ducting into dust magnets.

Do: Maintain, clean and monitor — Don't: Set it and forget it

Even good systems degrade without maintenance. Filters that become clogged, ducts or connections that leak, and overfilled collection bags or drums all have a way of creeping up on you in a busy shop. Nearly full collection containers, bags or drums do more than reduce capacity; they can alter airflow dynamics affecting every machine in the chain.

Establish a schedule for emptying collection bags/bins before they’re topped off and consider two-thirds as “full.” Overfilled bags can come loose or make them so heavy that they’re difficult to empty.

For smaller shops, filters should be inspected at least monthly; for larger, busier shops a weekly inspection would not be excessive. If filters are cleanable, clean them; if not, replace them.

Check connections and ducts for leaks everywhere; the more leaks, the lower the cfms. Measure airflow periodically with a basic handheld anemometer, record the stats, then watch for declining numbers that can signal a leak, obstruction, or a torn or a slipping bag.

Sweeping the floor is fine and encouraged, but fine dust tends to build up on horizontal surfaces, in joists and rafters, atop light fixtures and inside shop HVAC systems. This is where that shop vacuum, preferably with a HEPA filter, really shines. Every shop should have an ambient air cleaner (or more than one depending on shop size), that you use while on the shop floor, and for a half hour or so after shutting the shop down for the day.

Do: Filter and vent safely — Don't: Waste conditioned air or create hazards

Where dusty air goes after filtration is just as important as how it gets there. Venting outdoors removes nearly all fine dust, but then you’re also shooting heated/cooled air into the wilderness. You’ll do better, energy-wise, to return that air to the shop through high-efficiency filters, but only if filtration is truly effective.

If you smell dust, you’re breathing dust. Use HEPA-grade filters for indoor returns, so you aren’t recirculating dirty air. If local climate allows outdoor venting, install a backdraft damper on the vent, and a screen to keep out small uninvited guests looking for a warm place to spend the night.

This is also a good time to talk about noise control. A 3-hp collector can hit 85-90 decibels. Consider placing the collector in a central enclosure. Or, as long as it doesn’t extend the run too much, put it in a separate utility room lined with acoustic panels. Your ears – and household members, if your shop is home-based – will be grateful.

Do: Respect safety and fire prevention — Don’t: Treat dust as harmless

Wood dust is flammable. If the conditions are right, it’s explosive. Disastrous shop explosions are extremely rare and mostly occur only in very large facilities, but dust fires can happen in any size shop. A small, quickly spreading blaze can destroy equipment, wreak havoc on your business, and burn down your house.

Never mix workpiece materials. The swarf created working steel, aluminum or other metals can be hot, and running it down the same path as wood chips is asking for trouble. Either use separate ducting and collection for metalwork or thoroughly clean out hoses and ducts before switching materials.

Simple precautions and safety practices go a long way:

- Don’t suck up metal debris or nails that might spark against impellers.

- Do consider metal collection drums instead of plastic.

- Don’t let collectors run unattended without a heat detector/alarm.

- Do keep electrical panels, wiring and switches up to code for dusty environments.

Do: Protect yourself and crew — Don't: Expect machines do it all

No system captures every speck of dust, so use personal protection equipment to pick up the slack. You may be surprised at the difference wearing an N95 or P100 respirator makes when doing sanding, routing or even just emptying collection bags and bins, A box of disposable masks placed in work zones and machine areas not only boosts employee compliance, but gives you a visual reminder, too.

Dust is the nemesis of finishing. Fine dust particles will ruin a finish and may act as an ignition source for solvent vapors. Separate dust-generating areas from finishing areas. Dust collection and vapor ventilation should complement, not compete.

Even if it takes a training session, make sure employees are “dust aware” The best system doesn’t work unless everyone in the shop understands blast gate positions, bag or bin capacity, and basic filter maintenance. A written checklist on a clipboard at machines can help maintain discipline in a busy shop.

Bringing it all together

Don’t consider dust collection as mere housekeeping. It’s that, obviously, but it’s also an ecosystem joining airflow, filtration, maintenance and, above all, safety. The separate parts — collector, ductwork, filters, and shop layout — must function in concert. Dropping the ball anywhere along the chain affects everything.

A dust collection system designed with purpose is all about control of airflow, particle size, safety and energy, but all those basics must be covered in the design phase for effectiveness. Once implemented and regularly maintained, your shop may start smelling cleaner and your filters will last longer. If so, you’ll know you’re on the right track.

Don’t think of a finely tuned, effective dust collection system as an expense, but rather an investment in your health and a sign of professionalism. Customers who see a clean, breathable shop will know you care about craftsmanship right down to the air itself. In the end, the only thing that should linger at the end of the day is the scent of freshly cut wood — not the dust left behind.

Originally published in the January 2026 issue of Woodshop News.

A.J. Hamler is the former editor of Woodshop News and Woodcraft Magazine. He's currently a freelance woodworking writer/editor, which is another way of stating self-employed. When he's not writing or in the shop, he enjoys science fiction, gourmet cooking and Civil War reenacting, but not at the same time.