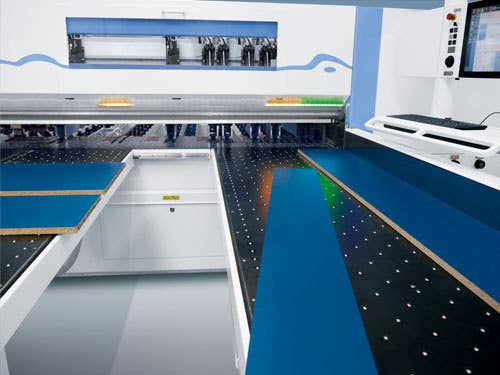

New edgebanding applicator from Nordson

Nordson will present the EB 60 Flex edgebanding applicator, which expands on the proven slot nozzle technology of the company’s EB 60 V adjustable slot applicator. “This new applicator maximizes…

Nordson will present the EB 60 Flex edgebanding applicator, which expands on the proven slot nozzle technology of the company’s EB 60 V adjustable slot applicator.

“This new applicator maximizes edgebanding production efficiency with volume compensation that means even the first panel after a coating width change is saleable,” according to the company. “EB 60 Flex applicators optimize material use and production efficiency saving manufacturers material cost and maintenance time while improving product quality.

“Volume compensation eliminates introduction of air or adhesive squeeze-out during coating width changes so accurate, consistent adhesive coating is applied. Adhesive volume is equalized inside the EB 60 Flex applicator so no purging is needed between width changes.

“These edgebanding applicators easily integrate with a wide variety of OEM systems and software. There are EB 60 Flex applicators for use with a variety of hot melt adhesives including ethylene vinyl acetate (EVA), polyolefins and reactive polyurethane (PUR).

“A motorized version of the EB 60 Flex applicator automatically adjusts coating width using input from a touch-screen control panel. And, a hand wheel adjusts the nozzle width for the manual version. The applicator’s nozzle closing device covers the nozzle opening during production/machine stops, even overnight; this feature is particularly useful in keeping PURs from curing.”

For information, visit IWF booth No. 5052 and www.nordson.com.