Updating a classic

In one form or another, Rainier Woodworking Co. has been making cabinets for Puget Sound customers since 1957. Scott Reader bought the Tacoma, Wash.-based shop in 2001 and has established…

In one form or another, Rainier Woodworking Co. has been making cabinets for Puget Sound customers since 1957. Scott Reader bought the Tacoma, Wash.-based shop in 2001 and has established an efficient nested-based manufacturing operation, building primarily off the 32mm system.

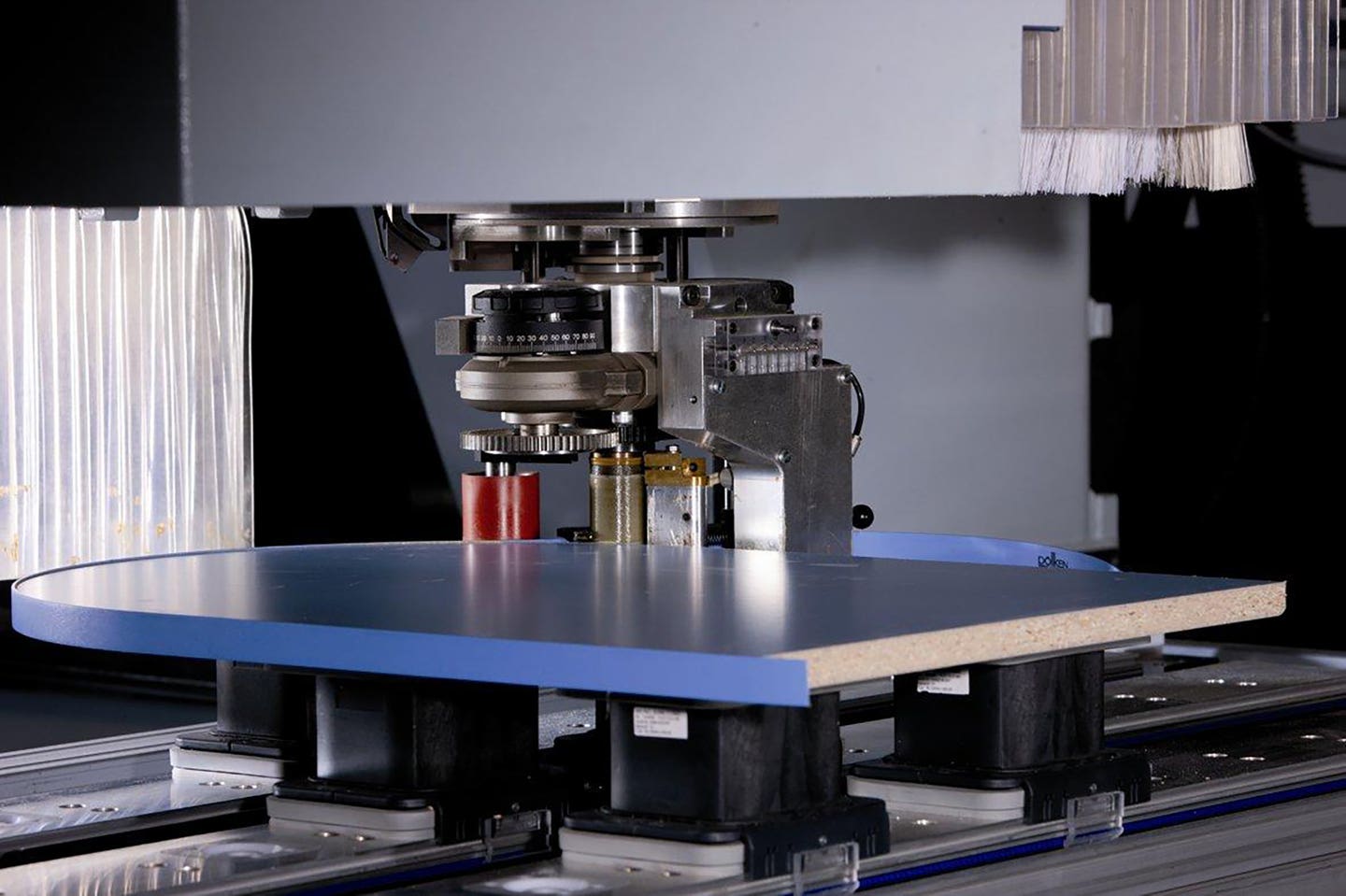

Rainier once had 138 cabinetmakers, producing 16 sets a day in the 1970s, according to Reader. Times have obviously changed. Today, the shop has 38 employees — including designers, craftsmen and office personnel — filling more than 300 custom and semi-custom orders per year with the latest CNC hardware and software.

“To grow the business we did a couple of different things,” Reader says. “We changed the business processes. There were only five employees when I purchased the business and they were wearing so many hats. We got them focused on schedules and employed them at using different tools.

Entrepreneurial spirit

Reader grew up in the Northwest during what he calls the “pre-Microsoft” era. He attended the University of Washington at Tacoma and completed several graduate programs, earning an MBA at the Kellogg School of Management and a masters degree in engineering at McCormick School of Engineering, both at Northwestern University in Evanston, Ill.

“After school I worked as a management consultant for a while, but I wanted to have a family and not travel as much as I had before. I also wanted to do something entrepreneurial. So my wife and I began to look into businesses to purchase. We looked at 83 businesses in total, all low-tech manufacturing firms. The one that both my wife and I could agree on was Rainier Woodworking,” Reader says.

Reader’s philosophy of running a successful shop, based on his own experience, is figuring out if an employee falls under the category of designer, engineer or dictator. He believes every individual naturally falls under one of those. He says the designer creates a vision, while the engineer puts it together and the dictator makes a decision and, if it doesn’t work, makes another one and moves on.

“The argument is figure out who you are and have the roles defined. As an organization we need to balance this out,” Reader says.

“Woodworking is a bit like farming, it’s become very high-tech. Farms are a lot larger now and the equipment is an incredibly sophisticated capital investment and that’s what woodworking is. It’s about the software and machinery, which requires a level of intelligence. So just think of it as a high-tech business: the processes, science and methodology are sophisticated. You have to know it.”

Puget Sound and beyond

To illustrate the shop’s wide market, Reader points to a large map of Washington behind his desk.

“We focus on the central Puget Sound area and go up to the north end of Lake Washington. We can go up towards the Canadian border, but we don’t go south of Olympia. We go from the far west of the peninsula to eastern Washington where there are a lot of resorts. Most of our product goes up the east side of Seattle to the Bellingham cascades area.”

The shop predominantly serves the residential market. “I would say the homes we work in are mainly high end. There are a lot of large mansions, 3,500-sq.-ft. homes we work in,” Reader says.

Work is acquired mainly through a network of contractors and remodelers. The company also works directly with homeowners, most of who have been referred.

“We are the worst at promoting ourselves. We suck at sales and marketing,” Reader says. “Our business grows from customer referrals. We don’t do any advertising. In 2001, I opened up a number of showrooms, did advertising and a number of home shows, but we made a lot of errors and all of that was not very profitable. So when the economy went down we focused on our core customers, the wholesale approach, looking at builders and remodelers so we could have an ongoing relationship with them for repetitive sales.”

The Puget Sound customer wants a contemporary look with hints from the past. Dark stains and paints are in, according to Reader.

“I look at our design style kind of like Eddie Bauer merchandise — it’s got a style of its own. It’s not super-casual. It’s elegant, but modern. That’s what they want in the Northwest: simplistic with grain matching and a touch of Shaker design. I’m happy to accommodate anything. I prefer to do Euro-type construction. It’s the most efficient use of material and, if you install it correctly, it’s incredibly beautiful.”

Into the future

At this point, Reader says, “We are not trying to grow the business. The business is growing us.”

The plan going forward is to expand the shop. “We’re at 21,000 square feet and we’d like to have a 35,000-square-foot open and modern facility, which would require a move. No little separate rooms and ramps like we have here so we can organize our workflow a little better. And we need more room to house more stock. It’s definitely feasible,” Reader says.

He always has one eye on the competition, which he says is currently offering an inferior product at a lower price. Reader would actually prefer competing against other “high-end” shops.

“The competition is dominated by commodity players, giving what they think is the right price,” he says. “There was a company around here, no longer in business, that was known as the high-priced one. They were good for us to compete against because they were helping the homeowner understand there’s high-end and low-end cabinetry. Right now there’s nobody else promoting the high end.”

Contact: Rainier Woodworking Co., 3865 Center St., Tacoma, WA 98409. Tel: 253-272-5210. www.rainierwoodworking.com

This article originally appeared in the February 2015 issue.