Turn & Burn

Securing sheet stock on a CNC bed is a large part of the machining process. Clamps, jigs and vacuums hold the material steady while the spindle moves. But when it comes to turning parts on a CNC, everything changes. That’s because the work is no longer stationary: the wood moves too.

Securing sheet stock on a CNC bed is a large part of the machining process. Clamps, jigs and vacuums hold the material steady while the spindle moves. But when it comes to turning parts on a CNC, everything changes. That’s because the work is no longer stationary: the wood moves too.

There are machines that are built specifically as CNC lathes, and there’s also a rotary indexing accessory for most of the major manufacturer’s CNC routers. The indexer looks like a wood lathe, and it holds work between centers and rotates it or else holds it in a fixed, indexed position while the spindle and tooling do their job. It’s usually an optional accessory or an aftermarket purchase: call your CNC supplier to see which unit fits your existing machine(s). Some 3-axis routers can handle turning tasks, where the servo drive is operating continuously like a wood lathe’s live drive. But speed can be an issue, as can heat build-up. A rotary indexing accessory will allow the part to be presented one face at a time and completely milled, then rotated several degrees to a new face where the operation is repeated. This will result in a ‘turned’ piece that has never actually turned more than one revolution. It is more of a rotary mill than a lathe, but the results are the same.

Parts can be designed in many CAD programs and saved in a library, as most of the turning that is done on CNC lathes is actually duplication. Parts such as posts and columns, stair balusters, newels or furniture spindles are made many times over, and each one is an exact replica of the original pattern. Some artists also use CNC turning as a way to produce a more refined and accurate prototype or original part than they would be able to achieve on a manual lathe using handheld tools. But the greatest commercial value is in the machine’s ability to repeat, and that has earned a home for it in shops that produce everything from pool cues to mallets, flagpoles and truncheons.

Domestic manufacturers

Laguna Tools (lagunatools.com) offers a small family of CNC lathes under the group name Turner, and they’re capable of creating anything from 6’ decorative wooden columns to baseball bats. One of the more user-friendly aspects of the line is a hand-held controller that is simple to use. Plus, the machines are also compatible with most software formats, so implementing designs isn’t a huge challenge. The lathes come with liquid-cooled spindles because eliminating heat build-up is critical in long production runs. Among the offerings are machines that can turn out parts that are 46”, 60” or 72” long. In addition, there is one unit that is essentially designed to make baseball bats in five minutes, and another, the 4-axis CNC 2’x4’ Turner, that is available in a “two-up” version with two spindles and two rotary axis, for even higher turning productivity.

ShopBot’s Rotary Indexer (shopbottools.com) will turn one of the company’s small- to mid-sized routers into a CNC controlled lathe. The Indexer lets a woodshop cut full three-dimensional objects on a ShopBot. Like a lathe, it provides a fourth rotary axis for turning a part, but it also provides precise ‘indexed’ control over rotation. That means a woodworker can create standard lathe work such as spindles, newel posts and table legs, but also mill 3D sculptures. The rotary indexer comes in three different sizes (3”, 6” and 12”, depending on the machine you own) and can be purchased with new tools, or retrofitted to older ones.

Legacy Woodworking Machinery (lwmcnc.com) in Springville, Utah, started out with machines that used routers to create work in the round such as fluted and spiral balusters. Today, the company offers a number of machines designed for both panel and turning work. The Artisan II, for example, is a 5-axis hybrid CNC, and its framework is built of 11-gauge folded steel panels. The frame and gantry are welded, not bolted together, to withstand years of continuous motion and stress. The rack-and-pinion drive system provides high-speed positioning, and the industrial-grade motors and digital drives provide superior torque. Either a 5-hp MTC spindle or a 13-hp ATC spindle can be used on this machine. ER32 collets allow you to use ½” shank router bits for tool-based machining, as well as precision carving. The Artisan II is available in several sizes, with a working envelope ranging from 30” x 48” to 30” x 96”, and a swing diameter of either 11” or 15”. The 4-axis turning system combined with Legacy’s CCAM4 software allows you to program turned parts that feature beads, coves, flutes, reeds, joinery, rope twist, barley twist, hollow spirals and much more.

Camaster (camaster.com) is located in Cartersville, Ga., and one of the company’s CNC routers can be paired with powerful yet relatively easy to use software to closely mimic the artisan’s skills seen in moldings, arches, carvings, corbels, as well as in columns. Camaster routers are offered with an indexing lathe, which makes 3D carvings on cylindrical parts a snap.

Techno CNC Systems (technocnc.com) offers a fourth axis upgrade that allows the operator to route an intricate 3D carving on a cylindrical surface, or index a part by rotating it a set number of degrees. It’s designed more for working on cylinders than creating them. It comes complete with a three-jaw chuck and tailstock, plus a linear guide track for easy tail stock movement and center alignment.

ShopSabre (shopsabre.com) offers a rotary indexing head that essentially turns a 3-axis machine into a 4-axis one. The device, called On-Table 4th Axis, makes it possible to create chair legs, railing posts, gunstocks, and more. As with most indexers, it will also turn the work slowly so that the tool can create ropes and other threadlike designs on balusters and posts.

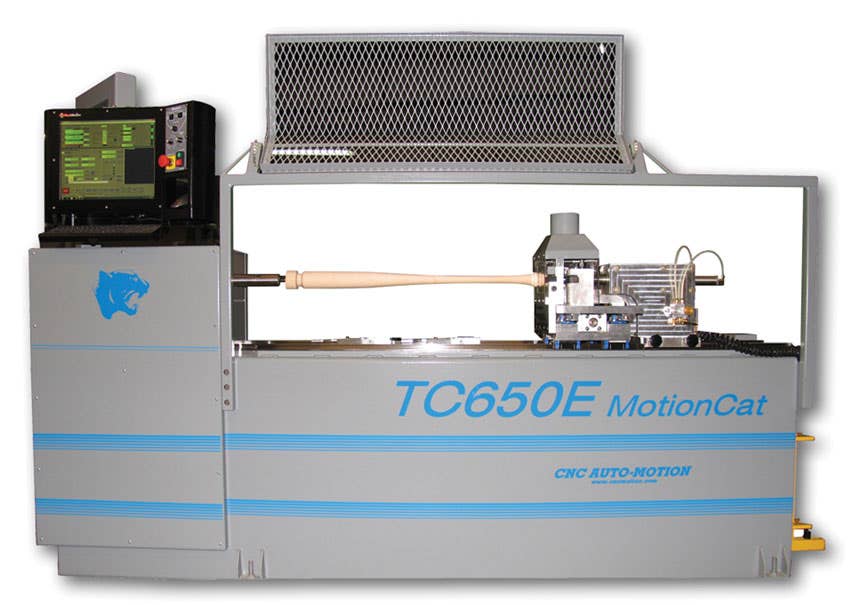

CNC Auto-Motion, based in Warren, Pa., (cncmotion.com) offers the Motioncat TC650E. This is a 2-axis CNC controlled wood turning lathe that was specifically designed for turning spindles, posts, columns and baseball bats. Profiles are designed in CAD/CAM software that is provided with the machine, and they’re stored on the control panel for easy recall. This eliminates the need for changing templates between jobs, which can be time consuming and expensive. The lathe runs on single-phase power, so it can operate in small hobbyist workshops or even a garage. Standard features include a flip-up safety guard and a dust extraction hood, as well as a center punch mounted on the machine. There are a number of videos on the website showing it in action.

For larger shops and projects, CNC Auto-Motion recently introduced a family of heavy-duty 3-axis computer-controlled turning lathes. The Columnmaster CNC Lathe is capable of accurately turning a wide variety of finished products such as columns, both large and small, rope twists, and newel posts. These lathes are capable of automatically turning columns up to 24” in diameter, with a maximum length of 16’. An automatic, six-position tool changer allows the operator to set up several profiles and change tooling quickly. The lathe isn’t restricted to wood: other foam and plastic columns might also be good candidates (check with the manufacturer).

Imported machines

Intorex Woodworking Machinery (intorex.com) is a Spanish manufacturer of CNC lathes with offices in the U.S. and Canada. The company’s CKX 600/1300/1600 can handle stock 23-1/2”, 51” or 63” long. It is equipped with two independently controlled cutting gouges, one for roughing and the other for finishing. Plus, it has an additional hydraulically controlled gouge for rounding. An automatic hopper feed loading system is standard on this lathe, and it also has programmable and variable spindle speeds, along with two rear overhead hydraulic back knife units for operations such as doweling. The machine can be equipped with an optional B-axis with a milling head (for twisting and/or fluting), or a sanding head with a narrow belt (for sanding turned and/or straight profiles). Programming is done with pre-installed, Windows-based, proprietary Intoredit software, and it can either take place on the machine controller or on a remote PC/laptop with transfer via USB key. The CKX is suitable for one-off specials, short batch runs and long production runs. Intorex also has three other models.

The Chinese company Style CNC (stylecnc.com) has been around since 2003, and offers seven varieties of CNC wood lathes. They run the gamut from benchtop units to dedicated machines that turn out two baseball bats at a time. The German company CNC Step (cnc-step.de/en) offers a “Shapilling Kit” which turns its High-Z CNC router platform into a CNC turning lathe. It’s a quick and easy conversion. And the Italian company Fapil (fapil.org) builds a number of tools for woodturning on a CNC lathe. These include profile tools, tenon cutters, gouges, cutters for wooden rings, parting tools, collets for lathes, screw-plate tools, and other accessories.

Before investing in a dedicated CNC lathe or a rotary indexer for your existing machine, check with your CAD/CAM software supplier. Unless you’re looking at large volumes, the machine you already own can probably make most of the ‘turned’ parts that you need, using existing tooling and hold-downs. It just needs to be told how.

This article originally appeared in the October 2017 issue.