No trouble in River City

Hard work and dedication has paid off for Damon Rebhahn, owner of River City Custom Cabinetry in Atlantic Beach, Fla., a coastal city adjacent to Jacksonville.

Hard work and dedication has paid off for Damon Rebhahn, owner of River City Custom Cabinetry in Atlantic Beach, Fla., a coastal city adjacent to Jacksonville. Specializing in kitchens, baths and other home cabinetry products, his company offers turnkey services to the residential market.

Rebhahn started the business in 1994 at 23 years old when he rented a 3,000-sq.-ft. space and pounded the pavement for customers. It has grown to have more than 30 employees and $3 million in annual sales.

“It took a lot of hard work, a lot of late nights but I wasn’t tied down to a family at that time. Obviously when you start something like this you’ve got to give 110 percent, so the first three to four years I worked until midnight, sometimes 2 a.m.,” says Rebhahn.

Starting off

Originally from La Crosse, Wis., Rebhahn moved to Jacksonville in sixth grade where his father was stationed in the U.S. Navy. He took an interest in woodworking in middle school, participating in state competitions and making an elaborate grandfather’s clock. In high school, he made reproductions of Queen Anne furniture.

Through a work study program in grades 11 and 12, he secured a job as a finisher at a cabinet shop. He also worked in the shop’s building and production departments while attending classes at the University of North Florida.

When a friend’s parents sought his expertise building their house, he didn’t think twice about opening his own shop. He used that job and several references to gain new clients and the work snowballed. By 2001, he built his 15,000-sq.-ft. shop from the ground up.

“Mostly all of our clients are residential builders and interior designers for homes around here and in Ponte Vedra Beach, with some down by Palm Beach and a few in Orlando. It’s all residential. We don’t get into commercial. The average homes we work start at $800,000 and go up into the $5-6 million range.”

Turnkey shop

Offering full design, build, finish and installation services, nothing is subbed out at River City.

“We used to sub out doors and other components but we had issues bringing those prefabricated parts here with this humidity. In 2003, we started manufacturing our own,” says Rebhahn.

“We’re trending towards flat panel doors, a more modern style panel cabinet. Most of our work is in newer homes and [customers] want the cleaner lines. Right now, our paint-grade woods are all soft maple. We try to bring our wood in here and leave it sit to get it to the right moisture level and get it acclimated. We’re also using a lot of rift cut white oak and walnut.”

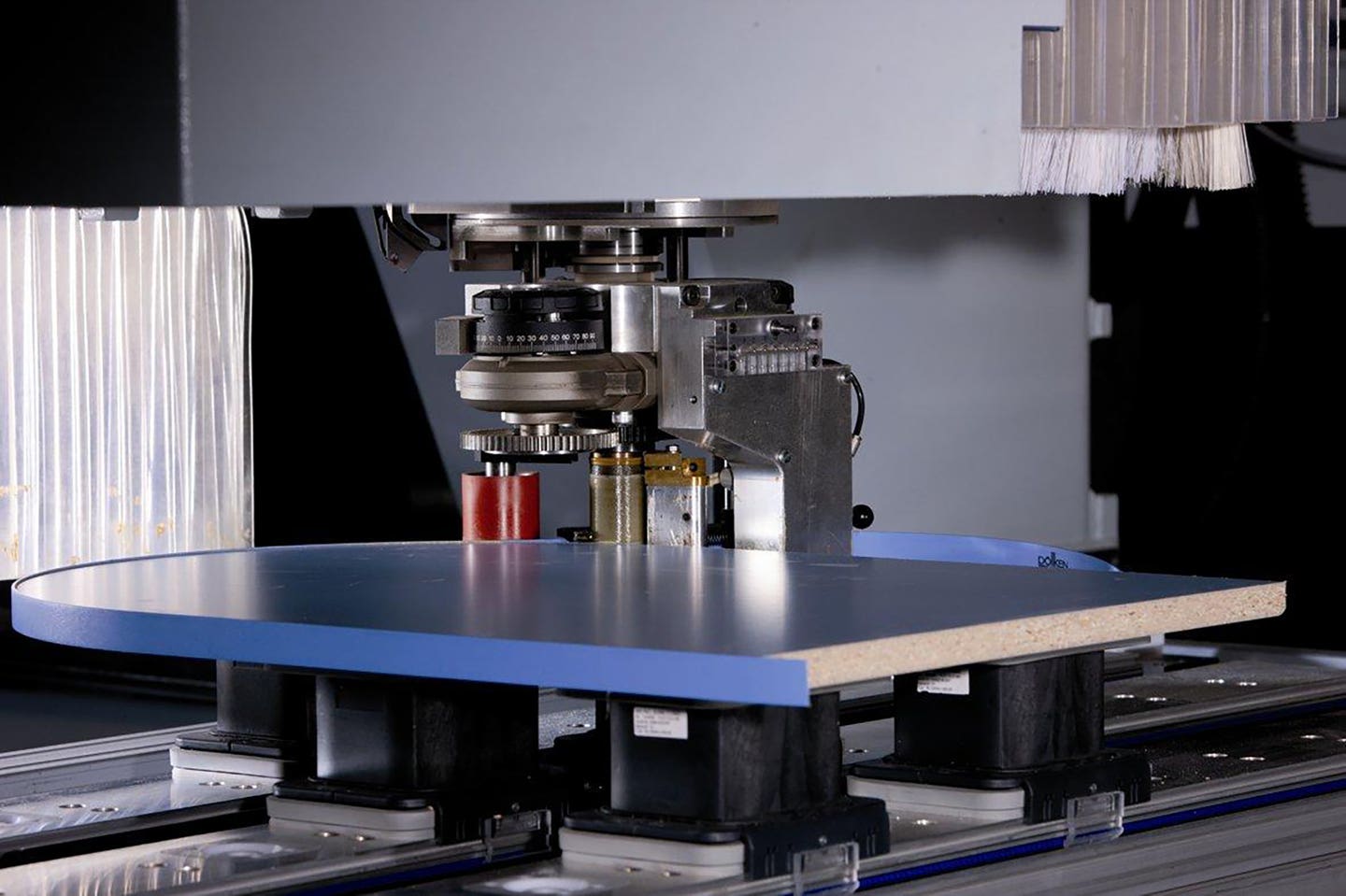

The shop’s equipment includes a SCM CNC router, edgebander and wide belt sander, two spray booths, and a PMK door machine. The employee count ranges from 28 to 32. Keeping a well-trained crew on board is extremely difficult, Rebhahn says.

“Our turnover rate can be pretty high. Last year I was pretty shocked when my CPA told me how many had turned over. There are just a lot of kids who will come here thinking they can do it and they can’t. We try to train them, we give them a chance, and it’s unfortunate the younger kids today are not taking this skill set as a career path.

“Around here they’ve closed our skill centers and they took woodshop out of most of the schools in Jacksonville. Another thing that’s unfortunate is we try to reach out to schools to get kids to come here and we just get no response. We’ve been trying to get proactive. We emailed them something to put on the board for the kids, but nothing happens.”

Number crunching

Rebhahn made strategic upgrades to the shop in 2007, starting with a 6,500-sq.-ft. addition for a spray and finishing area, followed by the purchase of an SCM Routech model 210 flat-table CNC router in 2008. Unfortunately, this coincided with the Great Recession that cut his production in half by 2009.

“Last year we hit $3 million in gross revenue, which is our target. During the recession we were right at a million or under. We would like to hit $3 million again this year. That’s the best we’ve done even prior to 2009 and is kind of my sweet spot.”

The recession left him feeling vulnerable and hesitant to continue pushing forward the way he had been. He was down to 11 employees and admits it was a challenging time.

“It was like the water was turned off. We were trying to save on electricity, sand paper usage, everything. You critique everything you possible can to squeeze every dollar out.

“I think I’m going to try to be a little smarter in purchasing equipment. I will try to stay out of debt. I just maintain all of our equipment as best we can to keep costs down.”

Rebhahn adds he is fortunate to have a good relationship with several other residential shops like his in the area.

“It’s not a cutthroat business. We call one another if a machine is down or someone needs help. We look out for each other.

“Our biggest focus is trying to educate the homeowners about what they’re getting from us. There are lots of one-off shops selling a modular line so our biggest issue is educating the homeowners and contractors about what they’re getting.”

A better balance

Since the recession, Rebhahn’s seen an increased consumer interest in premanufactured cabinetry. He is adamant about avoiding that route and refuses to make it any part of his business.

“We don’t do that. It’s not me. I enjoy what I do. I do the manufacturing. I can give them what they want and it’s all custom. It costs a little more, but if you educate them it’s a lot easier. We can adjust the price more easily to fit into a client’s budget. They might want inset doors but they’re more money, so we’ll do a full overlay. Or we can go from a plywood interior to melamine interior. There are a lot of options.”

His goal now is to maintain what he has and introduce slow growth, keeping the volume at 50 to 60 jobs per year.

“I don’t want to get ahead of myself because we don’t know when that next recession will happen. I don’t want to go through what we went through from 2009-2013. It made me more attuned to what’s going on and what not to do. I was very fortunate to make it through because a lot of shops didn’t.”

Rebhahn is relieved to now have a work/life balance where he can enjoy his personal time with his wife and children. Things weren’t always at the same pace.

“I have a young family still, an 8-year-old and 11-year-old, and try to find time for them. Before I was married, before I had my son and daughter, I was always working on the weekend and nights so I’m just trying to find that happy medium.”

Contact: River City Custom Cabinetry, 1863 Mayport Road, Atlantic Beach, FL 32253. Tel: 904-247-0807. www.rivercitycustomcabinetry.com

This article originally appeared in the April 2018 issue.