Catching Up with CNC Software

A comprehensive guide to the latest releases, new features and recent corporate developments.

Confusing. Overwhelming. Why is it written in engineer speak instead of English?

Those are the initial reactions of many woodworkers to new software for their computerized numerically controlled (CNC) routers, whether it’s for computer-aided design (CAD) or computer-aided machining (CAM). One core problem is that that operating this equipment seems to be a marriage of two very distinct professions – cabinet/furniture building and computer programming – and on the surface they look like they share few core attributes. But on reflection, that’s really not true.

Both are creative endeavors that use advanced tools to build complex projects, whether the casework is virtual or physical. Essentially, only the tools are different. It takes a bit of effort to induce a mind that was trained on table saws and routers to learn new ways. And maybe a thimbleful of courage, too, to take on so much that is new and intimidating.

Thankfully, there is help.

One of the most intuitive and easy to master packages is published by KCD Software (kcdsoftware.com). The company provides free live tech support and has a strong focus on woodworking, offering programs for designing cabinets, closets and doors, plus both CNC and traditional manufacturing.

This is software that you rent, and there are four levels to choose from. They currently run from $95 to $295 a month, with discounts when you pay for a year at a time. The basic package, Designer, lets a woodworker create 2D and 3D graphics such as elevations and dimensioned drawings.

The next level, Professional, adds estimates, proposals and various reports, plus integration with Cabinotch (cabinotch.us). That’s a system where shops can order the boxes in knock-down (RTA, or ready-to-assemble) format, and then add doors, drawers, finishes and hardware in-house. Built with American-made, formaldehyde-free hardwood plywood, the system has a patented interlocking joint that makes the cabinets a snap to assemble.

The third KCD package, Workshop, adds unit part sizing with construction details, plus cut lists and door and drawer order-generating tools. And the top-of-the-line suite, Commander, includes CNC coding, true shape nesting, one-button machining, and an optimizing tool for gaining maximum yield from sheet stock. KCD also offers dozens of short videos that explain all of the various commands and pull-down menus. As of last August, the company has begun offering software integration with custom powder-coated cabinet doors from Integra Doors in Greer, S.C.

Microvellum (microvellum.com) also has a strong understanding of casework and furniture. The company offers software solutions for design, drafting, engineering and solid modeling. It has an impressive library of cabinet drawings built up over two decades, plus integration of catalogs from suppliers such as Osborne Wood Products, who make components like decorative corbels and kitchen island legs. The software also imports hardware specs from many leading manufacturers including Accuride, Blum, Grass and Hafele, among others.

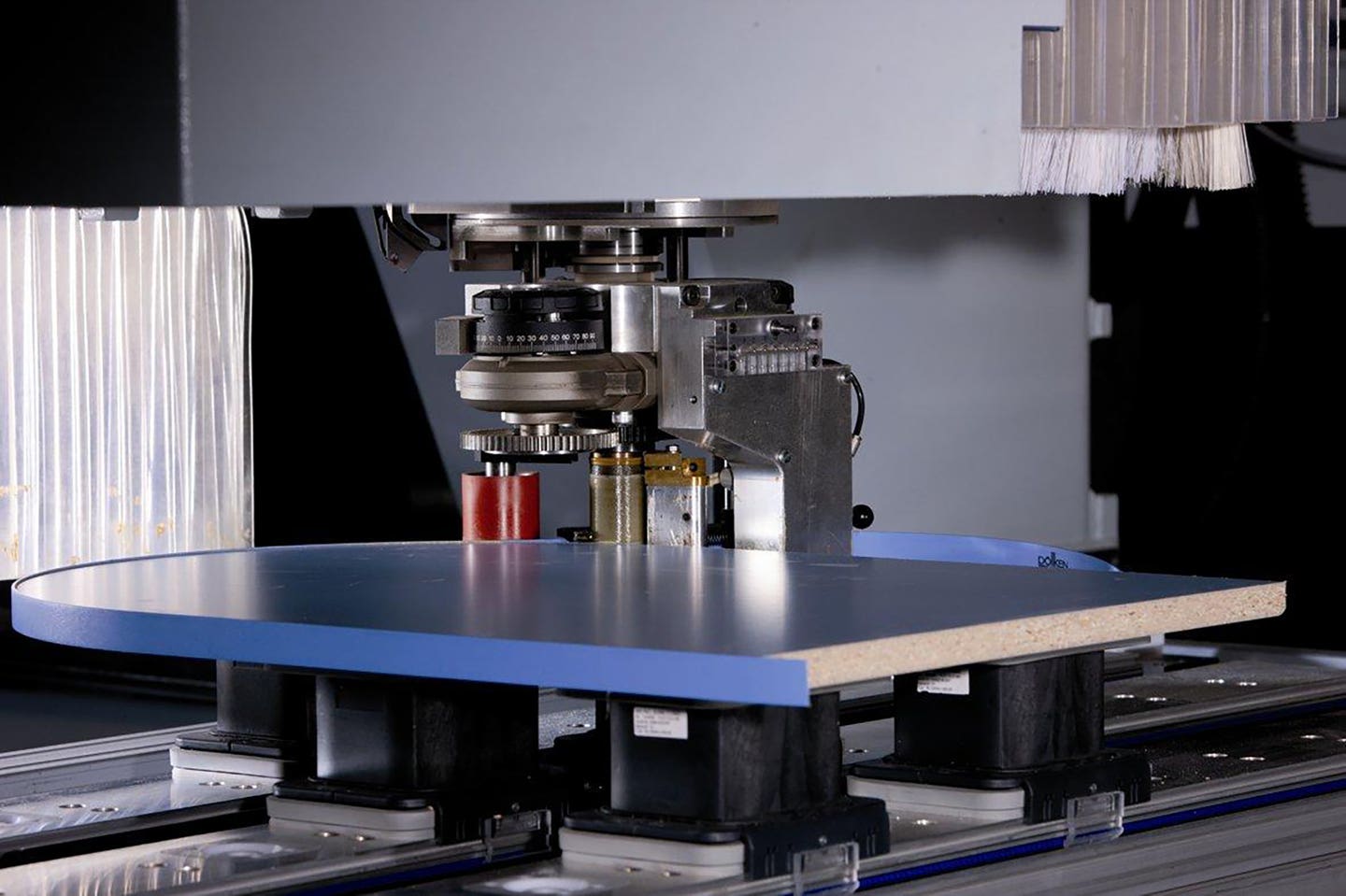

A woodshop can use Microvellum software to connect with and control machining centers, flat-table routers, through-feed machines, beam saws, vertical and horizontal drilling machines and CNC chop saws. The company has an open source post-processor solution that allows for fast setup and easy customization. It has partnered with many CNC machine manufacturers to ensure smooth integration with routers from Anderson, Biesse, C.R. Onsrud, Holz-Her, Homag, Multicam, SCM, Schelling, Weeke and other suppliers. And woodshops can use its reporting tools to create custom reports on virtually every aspect of production. Since all the information pertaining to every project is stored in a single database, building custom reports to access this information is easy and straightforward.

CNC Explained

Anyone who has taken drafting courses, or indeed even studied a set of blueprints over the past 30 years, is probably familiar with AutoCAD, the 3D CAD software from Autodesk. Translating a design into programming for a CNC becomes a whole lot easier after downloading the company’s free CNC Handbook course at autodesk.com. The goal of the book is to teach people with a technical background how to program and operate CNC machines. The 256-page PDF file explains every phase of the process in remarkable detail.

Autodesk has combined its most powerful software programs and services to create several packages, each at a single price, which are being marketed as Autodesk Industry Collections. For example, the Product Design & Manufacturing Collection includes everything a shop needs to design and make products, including in-canvas workflows for design, advanced simulation, 5-axis CAM, nesting and factory layout. Users also get access to the full breadth of specialized toolsets available with AutoCAD, along with new cloud-based technologies such as Fusion 360 that can unify design, engineering, and manufacturing into a single platform. That is, it makes CAD, CAM and CAE (engineering) software all work together as one. The Product Collection also includes rendering and data management software.

In 2016, Autodesk acquired Delcam, which is a wholly-owned, independently-operated subsidiary that grew out of a Cambridge University engineering project started in 1965. Delcam now offers digital solutions that automate and integrate design and manufacturing processes with the latest technology for CAM, additive manufacturing, simulation, robotics, and inspection. Among its products are PowerShape (3D CAD) and PowerMill, which is a robotics interface.

Mozaik Software (mozaiksoftware.com) creates Windows products for cabinets, closets and casework. The focus is on custom cabinet shops and cover the gamut from jobsite planning through design and manufacturing on CNC routers. It also includes applications for labeling, cutting and assembling.

Mozaik’s Design program ($50 a month) integrates seamlessly with Sketchup, opening up some interesting design possibilities. The company also offers a $199 program (buy, not rent) called ArielVision that is an easy-to-use plugin for creating near photo quality renderings in Sketchup. The Design software can be installed on a tablet or laptop and taken on the road to design in plan and elevation views. It can handle face frame, frameless, inset and full overlay cabinet door styles in the same design, and allows the woodworker to mix and match cabinets from different libraries. A designer can also create custom door and drawer styles, add hardware with specification documents, and select materials and textures. There is also the capacity to quickly add countertops and moldings to designs, and create custom molding profiles. As for speed, autofill functions can quickly fill a space, a wall or an entire room with library or custom cabinets, and the shop can then use the Product Editor to shape and change cabinets as desired.

Mozaik’s CNC Complete package ($125 a month) includes programs that handle everything from design to cut lists, nesting and machine ready G-Code.

Growing Resources

One of the biggest news stories of late in the CNC software world was the inclusion of Vero Software packages such as AlphaCam and Cabinet Vision in a new division of the Swedish parent company, Hexagon (hexagonmi.com). It’s known as Production Software, and it includes Vero Software, Fasys and Spring Technologies. The move sees the three acquisitions adopting Hexagon’s corporate identity and reflects the corporation’s broadening expertise in production technology.

Hexagon acquired Vero Software, which is a specialist in CAD/CAM software, back in 2014. The 2017 acquisition of Fasys brought tooling and resource management software, plus shop-floor automation and integration expertise, into the portfolio. And Spring Technologies, acquired in 2018, provides CNC simulation technology for G-Code verification and workflow optimization. This translates to more resources for woodshops as they grow.

The latest versions of Cabinet Vision and Workplan were featured at Wood Pro Expo and the Cabinets & Closets Conference in Charlotte, N.C. in March. Cabinet Vision for woodworkers generates photo-realistic images and, at the click of a button, lets users transition from art to part. They can create shop drawings, generate cut and material lists, formulate bids, apply production standards, maximize material yield, and more. The newest version of Workplan is geared toward optimizing logistical flow by letting users actually model their woodshops and localize inventory during the manufacturing process. In addition to tracking project status and making it easy to determine remaining job tasks, the system also manages purchasing needs and even tracks man-hours for efficiency.

Measuring a room for casework before actually designing the boxes can be a tedious task. Cabinet Vision now directly imports measurements from the Leica Disto S910 laser measuring tool. Leica is also a subsidiary of Hexagon AB. Vero’s Alphacam 2018 R2 has a new nesting engine that can deliver significant improvements in material yield. It also provides faster calculation times, along with improved feedback and graphics. And Cabinet Vision Version 11 now includes new rendering technology that provides users with nearly photo-like images, which woodshops can use as a sales tool. Plus, Vero’s WorkPlan software for ERP works with Cabinet Vision to let users organize workshop operations from design to completion.

Woodshops that have been using Mastercam software currently have a chance to participate in beta testing for the upcoming 2020 release. It can be downloaded on the website (mastercam.com) and will be supported through the Customer Forum, which is staffed with CNC applications engineers, posts writers, technical support people, software developers and QC engineers. The company is looking to release a new public beta version approximately once a month. Known issues, updated bug fixes, and other details will be delivered when a shop installs the most recent beta. The program requires a 64-bit version of Windows 7, 8.x or 10. The beta version is provided as part of an early access program and although it has been extensively tested, it has not yet been officially released so using it is at a shop’s own risk.

Mastercam delivers CAD/CAM solutions such as optimized pocketing to highly specialized toolpaths like 5-axis trimming. It has full 3D CAD modeling, easy pocketing, contouring and drilling, built-in nesting, plus engraving and aggregate tools among other resources. Designed to grow as a business grows, shops can start with what they need and upgrade to new machining techniques as needs grow.

Other Resources

Vectric (vectric.com) offers free trial software, training videos and files for download, to encourage potential users to give it a test drive. Its products include VCarve, Cut2D and Aspire. Cut2D program is designed for smaller shops that need to produce complex 2D patterns with profile, pocket, drill and inlay toolpaths. It has unlimited job and toolpath size, true shape nesting, and job set-up sheets.

CabMaster (cabmastersoftware.com) offers design and manufacturing software, including nesting options and door building programs. Its Designer 3D program lets a woodworker view a total price of each job by material, hardware and labor usage.

Cabinet Pro (cabinetpro.com) provides software to generate cut lists, material reports, labels, floor plans, dimensioned wall elevations, 3D renderings and more for the cabinet and door manufacturers.

Camworks (camworks.com) is CNC machining software for general industry, including woodworking.

SolidWorks (solidworks.com) is a 2D and 3D CAD package published by the French company, Dassault Systèmes. It is taught in more than 28,000 universities worldwide. One of its programs, Swood Design, acts as a booster for woodworking projects inside SolidWorks. Thanks to a set of features dedicated to wood and panel processing, Swood Design makes it easier and faster to make production-ready designs.

TopSolid (topsolid.com) from Missler Software is a manufacturing solution for modeling, simulation and production. Its program for woodshops, TopSolid’Wood, represents a genuine integration between design and production for the wood industry. A digital chain is created between the design office and shop to deliver consistency between the CAD and the CAM user interfaces. The latest version of TopSolid’Wood includes updates such as grain matching for nesting, an automated nesting process, advanced 2D functions and improved renderings.

CNC Exporter from Cabinet Solutions (cabinetsolutions.net) takes a woodworker from designing a kitchen to setting up tooling information, to EnRoute for nesting parts and creating G-Code. EnRoute is a program from Sai (thinksai.com).

The bottom line with CNC software is that a shop should begin any search by checking in with the hardware (router) manufacturer for recommendations, but temper that advice with opinions garnered from user groups and other resources online. Just because a machine manufacturer says a certain piece of software works best doesn’t mean it is so. This industry moves so quickly, there is probably something out there that is easier, faster, cheaper or simply better than the ‘free’ software that came with the machine.

This article originally appeared in the May 2019 issue.