Caribbean Made

Caribe-Craft in St. Thomas has transformed into a one-stop shop for projects big and small.

A warm tropical breeze, white sandy beaches surrounded by lush flora and palm trees, sipping drinks garnished with umbrellas as saltwater splashes at your feet. And the scene is set for a client meeting with George Munzar Jr., principal of Caribe-Craft Custom Millwork in St. Thomas.

His turnkey company provides custom cabinetry, millwork and much more for residential and commercial clients throughout the U.S. Virgin Islands. Started by Munzar’s father, George Munzar Sr., as Fine Woodworking Inc. in the early 80’s, the business changed its name and skillset in 2010 to take on large commercial projects. It operates from an 18,000-sq.-ft. shop with a dozen or more employees.

“There were mega hotels going up and they needed 50 to 60 rooms worth of furniture. They weren’t going to give it to a mom-and-pop shop with a standing table saw, a band saw and a router. They wanted to see someone with a large facility with lots of employees, and $2 million a year capacity – the kind of company where you have to have the capacity to evaluate a job correctly and be successful in the completion,” says Munzar Jr.

European roots

Munzar Jr. was born in the Czech Republic. His grandfather was a civil engineer with a large construction company that renovated villas and chateaus in addition to building industrial facilities and infrastructure projects. The business was lost to communism and the family immigrated to America for a better life when he was only three.

“We came to the U.S. in 1969. We landed in (New York) and had $28 in cash and zero English skills. And that’s how we got started,” says Munzar, who now speaks three languages fluently.

The family settled in Rochester, N.Y. and relocated to St. Thomas in 1978. Munzar Sr. ran an auto repair shop for several years until a customer offered some woodworking equipment – a few machines and hand tools – for sale. He jumped at the opportunity.

“He started focusing on all the major projects that were going on at the time. Back then St. Thomas was not very huge. In the 70’s and early 80’s, there was not much going on and the population was very small,” Munzar Jr. says.

That changed when cruise ships started pulling into port on a daily basis. The downtown stores were suddenly flooded with thousands of visitors and the fixture market took off.

“My dad got a contract to build all the Columbian Emerald stores throughout the Caribbean. His company completed about 50 of them with doing their showcases, built-in cabinetry, wall paneling, and more,” recalls Munzar Jr., adding that his father had the foresight and the means to procure land and build the current two-story shop.

The homecoming

As a boy, Munzar Jr. helped in the shop and showed an entrepreneurial spirit with a t-shirt business. He left St. Thomas to pursue woodworking and construction engineering at the Rochester Institute of Technology and Monroe Community College in Rochester.

“I ended up leaving and going to university but each year I returned, I worked for dad as a helper in the woodworking shop. I gained lots of knowledge from going to engineering school. I started sweeping floors and went to designing kitchens with Cabinet Vision for his company,” he says.

After college, Munzar Jr. and a business partner bought struggling bars in Rochester, Buffalo, and Tucson, Ariz., turned the businesses around, and sold them. Then he returned to St. Thomas and managed the shop floor.

“I was floundering around, didn’t know what direction I wanted to go. My dad roped me back into a stable lifestyle. I bought some land and decided to make my roots in the Caribbean and stay here once and for all and help him with his business.”

He has now been on the island over 30 years, guided the company through several expansions, which is where his father’s foresight to build a shop has really paid off.

“Since the biggest problem in St. Thomas is space, it’s such a huge premium. Having our own building has made this an accessible career for me and I was able to keep building it. If my father hadn’t built this place, I wouldn’t have been able to continue to this level like I did.”

Bigger is better

Munzar Sr. still builds furniture and kitchen cabinets for residential clients. Caribe-Craft is also a one-stop shop for architectural millwork, doors and windows, stone and countertop fabrication, signage, and hardwood sales.

“This market sector did not exist when I formed my company, it wasn’t here, says Munzar Jr. “It was in China and Florida, if anything. I brought that market sector to St. Thomas little by little. By getting bigger and bigger jobs, we developed a rapport and a trust with some of the bigger contractors on the island.

“I started studying the way that process worked, and I was literally, single handedly the only company that was in the tri-island area that could build a project that was $1 million plus.”

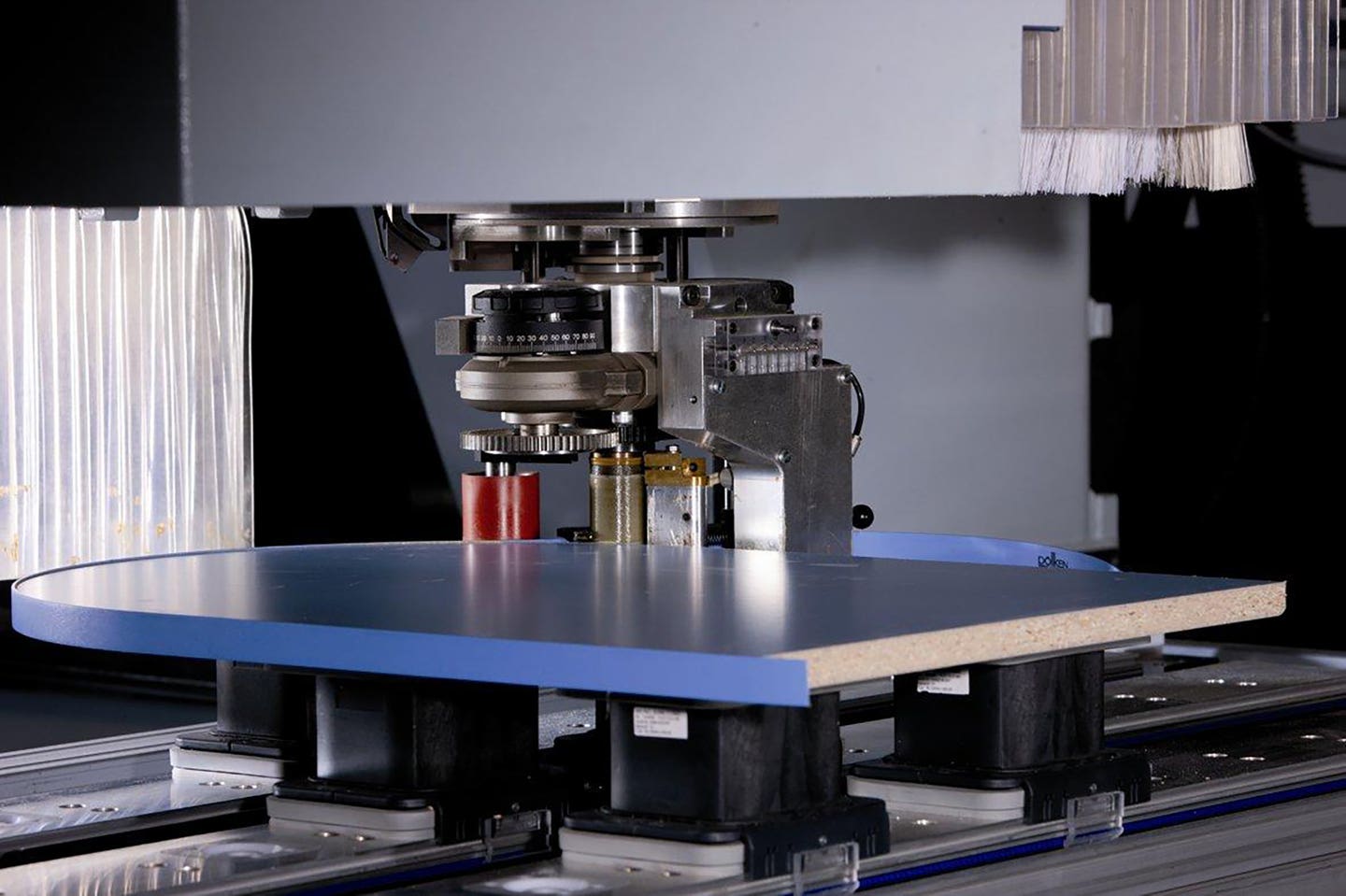

Munzar Jr. gives his father credit for having a high level of sophisticated equipment and working methods in the 80s, but today’s shop embraces more advanced technology. It features a ShopBot CNC router, Paolini digital panel saw, Hendrick vertical panel saw, and automated knife grinder. It has a library of over 700 profile knives.

About 70 percent of the shop’s business is commercial and government work. Residential jobs account for the rest. The ratio changes with the tide of tourism. The pandemic has nearly halted the shop’s two-year focus on hotel work, but Munzar Jr. is expecting more residential work will fill the void. As he puts it, his company knows how to ride the waves.

“I always keep my residential clients alive. Even when I’m working with the hotel guys, and they come knocking, I role my projects to George Sr. and he has turned into overflow. He works under my business license as a subcontractor for projects I can’t handle. A lot of times I’ll cut his parts on the CNC.”

Flying high

Most of the local contractors prefer Caribe-Craft because it’s easier than coordinating with offshore companies, according to Munzar Jr.

“Some contractors say we’re expensive but what it buys them is they can sleep at night. They know the millwork is going to be put in, that it’s going to be awesome, it’s going to be full quality, on time, on schedule and on budget,” he says.

There are several smaller cabinet shops on the island, most of which have a connection to Caribe-Craft. “Most of the little (shops) around here are ex-employees of me that broke off. We trained personally about 70 percent of all the guys trying to do something. And I have no problem with those guys. I’m happy for them and I can’t build everything, nor do I want to. And there’s a need for them but they can’t touch a large project because they don’t have the experience, they’re not qualified.”

Munzar Jr. recently obtained his pilot’s license, fulfilling a lifetime dream that will really make inter-island travel easier. He’s got his head in the clouds, literally, and feels the sky is the limit for the shop’s future success.

“Regardless of how bad the economy gets there’s always somebody buying something, somewhere. If you are good, you’re good. If you have good quality standards, you’ve got good service standards, if you have a long waiting line, what you can say safely is even when the economy retracts, there’s still somebody out there who’s doing a renovation,” he adds.

“Even the pandemic didn’t shut us down. We had a contract going into a beach club hotel. They subbed some things out but still gave us the hardest stuff. Whenever someone can’t make it, they call me.”

Contact: Caribe-Craft Custom Millwork, P.O. Box 302310, St. Thomas, VI 00803-2310. Tel: 340-774-9545. www.caribecraft.com

This article was originally published in the February 2021 issue.