All for one

Thanks to a hard-working team, multi-generation Chicone Cabinetmakers embraces complex, challenging work.

Whether designing an elegant kitchen, creating heirloom furniture or historic reproductions, Chicone Cabinetmakers in Montour Falls, N.Y. strives for the highest quality work through meticulous craftsmanship.

Formed in 2002, it’s part of Chicone Builders, a home construction and remodeling firm founded in the early 1950’s by the late Salvatore Chicone. The operation is now run by Vincent Chicone, Salvatore’s grandson, who says the current backlog extends beyond one year, which is beyond his belief after a previous lull.

“Six months ago, it came unhinged. It’s crazy how many people started talking about not only domestically made furniture but then they spent so much time in their houses they started wanting improvements and to change things,” says Chicone.

Chicone credits the company’s international success to his skilled and dedicated team ready to address any project, often learning as they go. There are five employees in the cabinetry division plus office help, and three to five employees in the construction division.

“It’s really the staff we have. The staff we’ve had and been able to hold through the last 20 years that haven’t gone anywhere and it’s just one big family on both sides of the business. We do things the hard way. I’m not interested in cutting corners and oftentimes that’s not economical.”

Boston and back

Chicone grew up in Montour Falls watching his father, David Chicone, work alongside his grandfather on homes throughout the Finger Lakes region. While he helped around the shop and learned how to work with tools, he never imagined a career there and went off to college at High Point University in High Point, N.C. for a business degree. He went to work in Boston where he found the corporate sector was not too appealing, so he returned to his hometown in 2002.

“I was balancing portfolios and sitting in office lights. It was horrible so I thought the snowball’s already rolling, this is something I might be interested in,” says Chicone.

“My wife (Sarah) and I came back, and the company was in the process of building a ridiculously huge house with six or seven bedrooms. The client, and it was a wonderful client, asked if we might be interested in creating all the furniture in this space. We did each room in a different period style, and because of that, it allowed me to have a pretty broad stroke in the furniture world in the kind of furniture that we can produce out of the shop.”

The shop added a website (chicone.com), which immediately attracted leads on a national scale, including work for Monticello, the historic plantation of Thomas Jefferson in the Piedmont region of central Virginia. “In 2005, we acquired Monticello as a client. We are authorized to reproduce and recreate their furniture. We started off with five pieces and we’re at eleven now,” says Chicone.

Broad exposure

Expansion outside of the company’s local market was paramount to its sustainability, according to Chicone.

“We’re in upstate New York. It’s not populous. We have a lake (Seneca) that basically insulates us for doing housework and some architectural millwork, but the furniture, it started off slow and now its international where we’re sending things.”

After the first Monticello pieces were completed, Chicone experienced fallback from the Great Recession and his concerns led to the creation of more solutions to deal with the ebbs and flows of the market. Diversifying product offerings was key, so the company began high-end custom cabinetry and architectural millwork leading to a plethora of work within a five-hour radius, and random jobs in other locations.

The production breakdown of the cabinet shop is about 50 percent kitchens and the rest split between furniture and millwork.

“We are in Washington, D.C., New York City, we travel. I look at my crew in the shop and I’m jealous, I want to be there building things on a day to day, but in real life I’m hustling to put out client fires. I’m going and finding new work. I’m drawing and designing three-dimensionally for the next job coming up,” says Chicone.

The company is currently wrapping up another historical reproduction project, a large commission for the University of Houston which is recreating Independence Hall on its campus and has contracted 70 chairs, including the Rising Sun Chair, used by George Washington at the 1987 Constitutional Convention.

Jobs are as unique as they get from one another, but that doesn’t stop any progress. Chicone says the company mantra is to find a way to make it happen.

“We don’t know anything about rice paper, so why would we be making a shoji? But we had a client come who wanted to do all of these screens. I said, ‘Let’s figure it out. How hard can it be?’ Well, it was really hard, but you just dive into it. That’s the way it’s always been.”

A charming setup

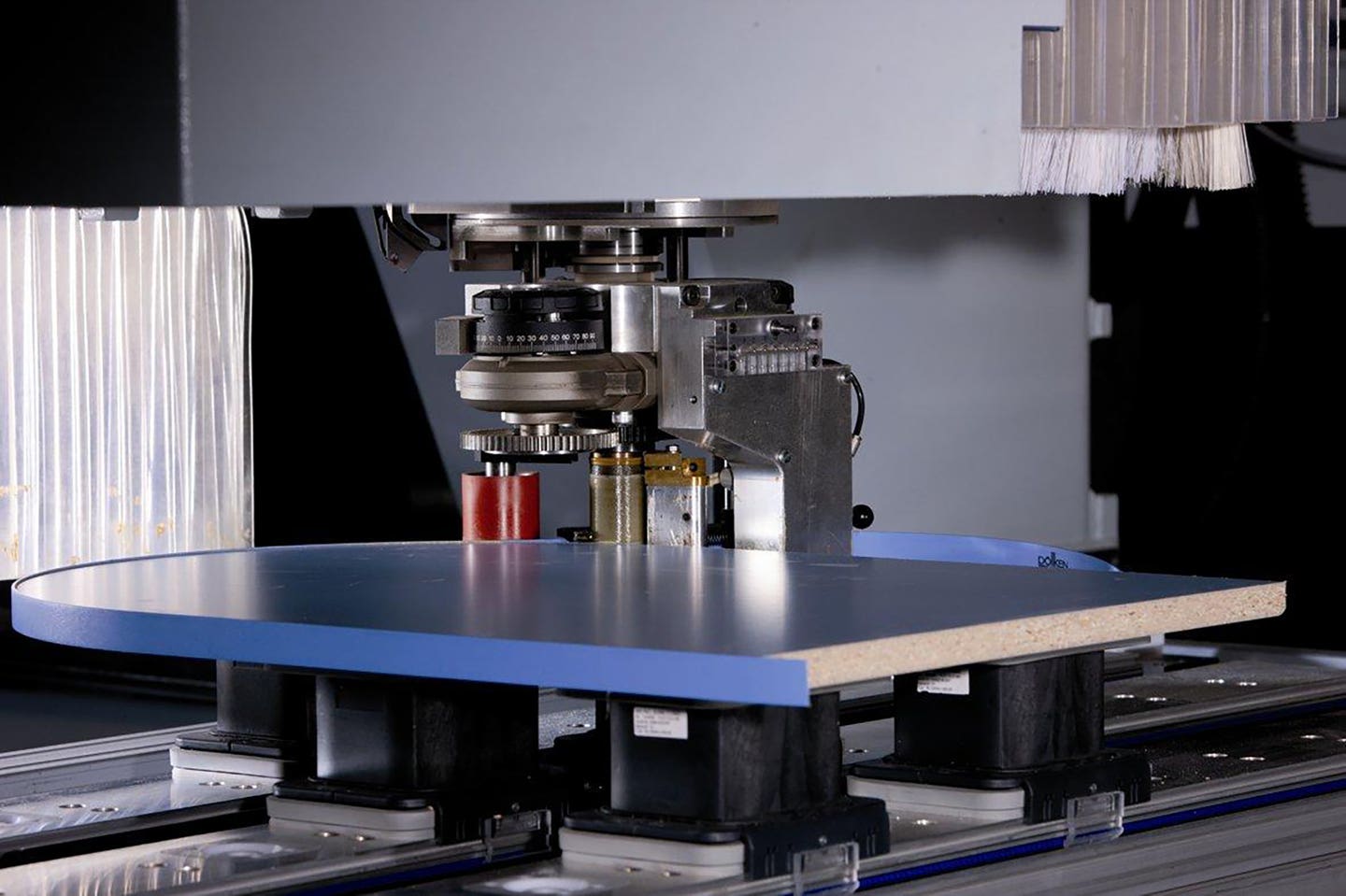

The facility layout is a series of buildings on several blocks at the entrance of Montour Falls, across from the Shequaga Falls and minutes from Lake Seneca. The two-floor shop is about 7,000 sq. ft. with handwork, machining and assembly downstairs and a ShopSabre CNC machining center upstairs. This building, along with a smaller office building next to it, has an aesthetic matching the historical homes in the area.

Across the way is a modern, 10,000-sq.ft. warehouse built in 2017 which is adjoined by the construction firm operation. This spacious, climate-controlled building houses a Cantek straight-line rip saw, Kentwood six-head molder and other tooling, as well as a wood inventory of 50,000 bf.

Chicone says automated machinery is crucial to his bottom line and particularly values his CNC for its ability to do fourth-axis turnings for bed parts and table legs.

“In today’s world you need to be able to operate CAD and CAM software and you need to have a CNC. The world of being able to pick up a hand plane and produce furniture and feed a family is no longer. It’s a weird place that we’re in right now.”

Chicone’s father still helps wherever he can, whether it’s painting for the construction company or doing errands for the cabinetry shop. His mother, Jennifer, works in the office. While he’d prefer additional craftspeople on the shop floor, Chicone, unsurprisingly, says they’re difficult to find.

“With the workload coming through we could use three to four more. In upstate New York, it’s a rarity to find somebody that wants to stick around, and you do everything you can to hold onto them. Finding young blood that wants to do this its hard right now.”

Learning opportunities

One solution to his employee shortage is a five-year apprenticeship program Chicone started about six years ago.

“This is a five-year grind for you to come through and when you’re done, you’ll know how to run everything in this shop. You’ll know how to run CNC equipment. You’ll know how to get on the CAD programming and design a kitchen and such,” says Chicone, who recently graduated his second journeyman and will welcome a third participant in the spring.

One of the issues Chicone faces is young, emerging woodworkers believing the trade is easy. He has to explain the reality.

“As you talk with parents and their 18-year-old boys and girls that come through, everything they’ve seen so far is a romance and we need to get over that. In the beginning, you’re going to have blisters, you’re going to sand until you can’t even believe you’re still sanding.”

He also runs a Windsor chair making program that attracts international students.

“In the spring it’s usually Japanese or South Korean students that are flying through. We’ll shut the shop down for a couple of weeks to hold it. Covid really put a ding in that and I really haven’t opened it back up yet.”

A labor of love

Throughout his 20 years of experience, Chicone has seen countless scenarios with the direction of the business due to wavering economic circumstances. He says having the right attitude and taking things day by day helps manage the stresses that accompany tough times.

“In 2019, we had a horrible year. It was worse than Covid for us. Everything dried up. Then Covid happened and it was literally my father and I in the shop just playing. It took that time for us to wrap our heads around that we’ve been over 70 years in the works, and all of this can fold. We decided to just take it day by day. There’s no sense in getting worked up about anything, and that helps a lot.”

Chicone makes it a priority to give his team room for growth and ensure that work is varied enough that they don’t feel they’re doing the same things repeatedly.

“I don’t want things to be stagnant for anyone. You hold on to your employees because you don’t know what’s going to happen. Tomorrow a huge contract could come through and I need all these guys, and they have amazing skillsets. Where would I go and find somebody like that?”

Interestingly, he also says his college business degree did not help him get the company to where it is today. Instead, it would have folded had he followed the model of putting economics first.

“As an employer, you’re the last to feed the family in a business like this. You put your employees first and with any luck, they’ll produce for you. I learned that from my grandfather and father. Make sure everybody else is happy first. At the end of the year, everything will work out, but there’s going to be some scary moments in between, and most employees don’t even know you’re just making sure to give them what they need.”

This article was originally published in the February 2022 issue.