TigerStop rolls out Precision Rough Mill

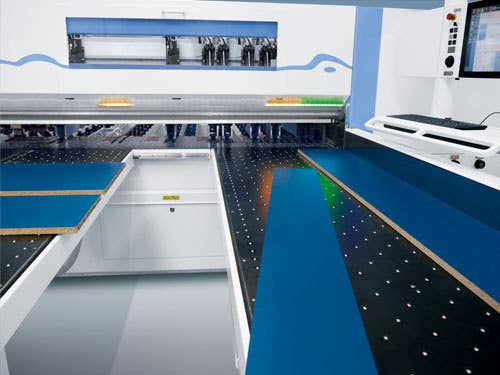

With the introduction of its optimizing ripping machine, TigerRip 1000, TigerStop will debut the new Precision Rough Mill at IWF, a flexible work cell that results from combining TigerRip 1000…

With the introduction of its optimizing ripping machine, TigerRip 1000, TigerStop will debut the new Precision Rough Mill at IWF, a flexible work cell that results from combining TigerRip 1000 with TigerSaw 1000 optimizing cross-cutting machine.

“Small- to medium-sized shops can now produce finish quality parts and achieve maximum material yield and productivity by ripping only what is needed, when it’s needed and by then only crosscutting the parts that are required to fill existing orders,” the company said in a statement.

“Most shops either buy their material pre-ripped, at a costly premium, or rely on an in-house sawyer to manually rip their own material. Both of these options involve extra, unnecessary costs and in the latter case, a lower than maximum material yield. These same shops also typically incorporate a manual process for material defecting, which is expensive and inherently inefficient, and use manual stops for cross cutting, which is time consuming and questionable in terms of accuracy. The TigerRip 1000, combined with the TigerSaw 1000, create the Precision Rough Mill, helping small to medium shops produce finish quality parts, lower their material costs, increase their yield, and adopt a true, just-in-time, lean manufacturing solution.”

For a demonstration, visit Booth No. 5747 at IWF.