Oliver Machinery Partners with Brother Membrane Press

Oliver Machinery has partnered with Brother Membrane Press to offer the best membrane press on the market for affordability and innovation. It’s massive construction guarantees longevity and minimal down time….

Oliver Machinery has partnered with Brother Membrane Press to offer the best membrane press on the market for affordability and innovation.

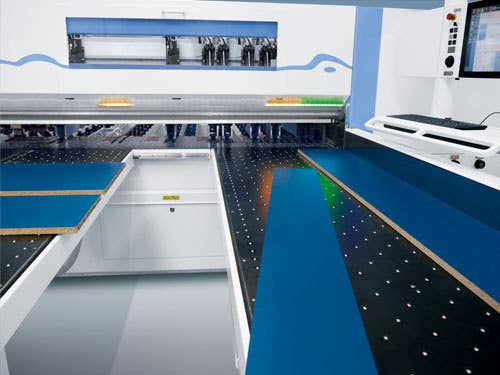

It’s massive construction guarantees longevity and minimal down time. The press can be operated with the Membrane or Membraneless. The two powered 53” x 105” trays enter and exit on the same side of the machine saving valuable shop space. One tray can be loaded while the other is being processed to increase production. Trays can be set to run automatically or manually. A 2 HP vacuum pump works with the membrane to ensure contour adhesion to even the biggest and most deeply profiled projects. State of the art operating system with 99-recipe memory controls all machine functions for consistent production. A well designed control panel with ‘off the shelf” parts facilitate quick troubleshooting and repair if needed. Multiple U-shaped heating elements guarantee stable working temperatures eliminating hot or cold spots throughout the entire chamber, thus allowing for few or no defects on even the largest panels.

The membrane press applies PET, PVC, Thermo-Transfer foil, wood veneer and other films to MDF, PB, steel, aluminum, wood, plastic and others, virtually any combination can be laminated by adjusting the temperature, pressure and time values. The table lift mechanism is a new-patented toggle type design that is warranted for five years. This system is capable of standing the high pressures associated with membrane presses, whereas other hydraulic type systems break down over a period of time and require expensive repairs and maintenance. This innovative press is a money making addition to any shop. 1,100 Installations Worldwide!

Contact information:

Dan Shaw

800-559-5065